Both aluminum and aluminum alloy conductors have the ability to conduct electricity, and the resistance of the two is different. The aluminum alloy conductor is added relevant trace elements in the aluminum conductor, so that its resistivity is lower than the pure aluminum conductor, which solves the disadvantages of poor mechanical properties, easy breakage and easy creep of pure aluminum cables, also avoids the investment problems caused by the high copper price.

What is an Aluminum Conductor?

Aluminum is a silver-white light metal with a density of 2.7 g/mm³, which is about 30.3% of copper. Aluminum has good electrical conductivity. Compared with copper, when the cross section is the same, the conductivity of aluminum per unit length is 64% of copper. If calculated according to the same mass of aluminum and copper, the conductivity of aluminum is equivalent to 200% of copper, which is greatly exceeded copper. Aluminum has good thermal conductivity, and its thermal conductivity is 56% of copper. Aluminum is acid-resistant, but not alkali-resistant, nor salt-spray corrosion-resistant. It has good plasticity and is easy to be processed by pressure. The disadvantage is that its strength is lower than that of copper and its welding performance is poor. But aluminum resources are abundant and its price is low.

Disadvantages of pure aluminum conductors:

- Poor mechanical strength and easy to break

- Easy to creep, requiring frequent tightening of screws

- Easy to overload and generate heat, existing safety hazards

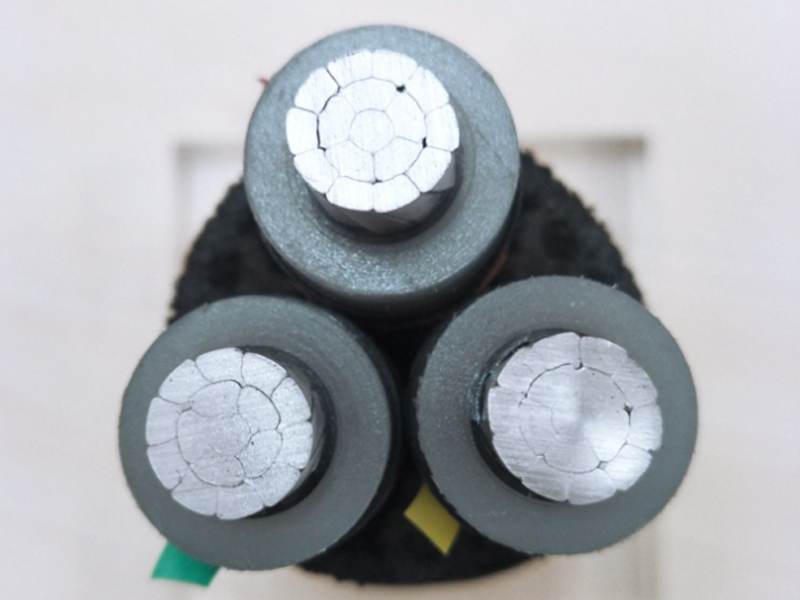

What is an aluminum alloy conductor?

The difference between aluminum alloy conductors and pure aluminum conductors is that aluminum alloy conductors add copper, iron, magnesium and other elements on the basis of pure aluminum, and these elements play a very critical role in aluminum alloys:

Copper: Increase the resistance stability of the alloy at high temperature. Copper is an important alloying element and has a certain solid solution strengthening effect. In addition, the CuAl2 phase precipitated by aging has an obvious aging strengthening effect. The copper content in aluminum alloys is usually 2.5% ~5 . 0%.

Iron: Increased creep resistance and compaction by 280%, avoiding the relaxation problem caused by creep.

Magnesium: Under the same interfacial pressure, it can increase the contact point and have higher tensile strength. The strengthening of magnesium to aluminum is obvious, and the tensile strength will increase by about 34 MPa for every 1% increase in magnesium. If less than 1% manganese is added, it can play a supplementary strengthening role. Therefore, the content of magnesium in most industrial deformed aluminum alloys is less than 6%.

Aluminum Alloy Conductor VS Copper Conductor

Aluminum alloy conductors and copper conductors have different electrical conductivity due to the difference in resistivity. The conductivity of aluminum alloy is 61.8% of copper. When we increase the cross-sectional area of the aluminum alloy conductor by two gears or increase it to 150% of the cross-sectional area of the copper conductor, its electrical performance is consistent.

The tensile strength of aluminum alloy conductor is only half of copper conductor (113.8:220 MPa). Since the density of the aluminum alloy is only 30.4% of the copper conductor, even if the cross-sectional area of the aluminum alloy conductor is increased to 150% of the copper conductor, the weight of the aluminum alloy conductor is only 45% of the copper conductor, which makes the tensile strength of the aluminum alloy conductor also has certain advantages over copper conductors.

Problems with aluminum alloy cables

- The problem of minimum cross-section

Currently there are currently only two types of conductors available for aluminum alloys. It is solid conductor and stranded conductor. The nominal cross-section of solid aluminum alloy conductors should not be less than 10mm². The nominal cross-section of the stranded aluminum alloy conductor should not be less than 25mm².

Since the stranded aluminum alloy cable is produced using the compression technology, the compression coefficient reaches 0.93, which greatly reduces the gap between the conductors, improves the heat conduction inside the conductor, and increases the carrying capacity of the conductor under the same cross section. But its minimum cross-section should not be less than 10mm²’, and the minimum cross-section given by the general manufacturer is 16mm².

Solid aluminum alloy conductors have poor power supply reliability and cannot be repaired after breaking. But stranded conductors are different.In some special places, the conductor of power cables should be copper instead of aluminum alloy conductors, such as: fire-resistant, high-temperature places, and public facilities with high safety requirements.

Due to the above-mentioned various objective and self reasons, its scope of application is limited. - Connection problem

The standard size of copper terminal and copper-aluminum transition terminal.The size of the copper-aluminum transition terminal is larger than that of the copper terminal in terms of length, width and diameter, and the comprehensive average value of the increment of length, width and diameter is about 30% (the length increases the most). Therefore, when selecting aluminum alloy cables, it should be noted that the wiring space of electrical equipment should be able to meet the connection requirements of copper-aluminum transition joints.

Conclusion:

Due to the good electrical conductivity and excellent mechanical properties of aluminum alloy conductors, the disadvantages of unreliable connection, poor mechanical strength, and easy creep of aluminum conductors are improved. The mechanical properties of aluminum alloy conductors are similar to copper conductors, and the electrical properties have the same conductivity as copper conductors by increasing the cross-sectional area. It will be widely used in power distribution systems.