Flexible cables originated in the early 20th century and were first used in aviation, military and other fields. The main characteristics of flexible cables are high flexibility, bending resistance, excellent mechanical performance, etc.

What is flexible cable?

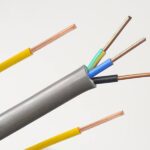

A flexible cable is a cable composed of multiple small copper wires or tinned wires as conductors, which are covered with materials such as PVC/PE/TPE as insulation, and have good flexibility and bendability. Compared with traditional wires and cables, flexible cables have the advantages of easy bending, high flexibility, strong reliability, long service life, etc., and are widely used in modern industrial production in fields such as robotics, CNC machine tools, medical equipment, electronic instruments, aerospace, etc.

Types of flexible cables

- PVC flexible cables: Insulated with polyvinyl chloride, this cable has excellent corrosion resistance, chemical resistance and electrical properties, but is brittle at low temperatures and is difficult to resist UV and grease.

- PE flexible cables: Insulated with polyethylene, this cable is non-toxic, environmentally friendly, resistant to low temperature, water, and corrosion, and is suitable for outdoor use.

- TPU flexible cables: Insulated with thermoplastic polyurethane material, this cable has excellent flexibility, wear resistance and oil resistance, and can be used in high-precision equipment such as robots and automated production lines.

Advantages of flexible cables

- Good flexible conductivity, not easy to break: Compared with rigid cables, the conductor of flexible cables is composed of multiple small copper wires or tinned wires, and has a larger contact area, so it has good conductivity and is not easy to break, thus ensuring the stable operation of the equipment.

- Small bending radius, easy to bend: Due to the use of flexible insulation and sheath materials, the bending radius of flexible cables can generally reach 2-3 times the cable diameter, while the bending radius of rigid cables is larger, limiting their application in narrow spaces.

- Long service life, can reach more than 10 years: The service life of flexible cables can reach more than 10 years, which can not only provide more stable, efficient, and safe guarantees for industrial production but also reduce maintenance and replacement costs.

Application of flexible cables

Due to its excellent flexibility and reliability, flexible cables have a wide range of applications. In the modern industrial field, flexible cables have been widely used in high-end fields such as robotics, CNC machine tools, medical equipment, electronic instruments, aerospace, etc. At the same time, in the consumer electronics market, such as laptops, mobile phones, tablets, etc., flexible cables have also been widely used.

Manufacturing process of flexible cables

The manufacturing process of flexible cables mainly includes conductor weaving, insulation and sheath making, appearance processing, and other links. Among them, conductor weaving is one of the key links of flexible cables, and the quality of weaving process directly affects the bending performance and transmission quality of the cable. In this process, the conductor wires go through stretching, weaving, and adjustment processes, and finally form a braided cable with a specific number of layers, conductors, and sizes; insulation and sheath making require the use of high-quality PVC/PE/TPE materials and undergo plasticization, extrusion or injection molding processes to form a cable surface protective layer with a certain thickness and flexibility.

Market prospect of flexible cables

With the continuous advancement and deepening development of industrial automation and digitization in the country, the demand for flexible cables in the industrial production and smart manufacturing fields will become increasingly significant. At the same time, in the consumer electronics field, as people pursue mobile devices, smart homes, and other products, higher requirements will be placed on flexible cables. Therefore, the future market for flexible cables is expected to maintain a good growth trend.

How to choose flexible cables?

When choosing flexible cables, it is necessary to consider factors such as the number of conductors, conductor materials, insulation materials, sheath materials, voltage level, temperature range, cable length, and bending radius according to different application scenarios and requirements. At the same time, it is necessary to pay attention to the selection of brand awareness and product quality to ensure the reliability and safety of the cable.

Flexible Cables VS. Ordinary Cables

Compared with ordinary cables, flexible cables have many advantages. Firstly, due to their design features, flexible cables can adapt to complex shapes and size requirements in various work scenarios. Secondly, flexible cables have a large bending radius and twisting angle, making them very suitable for complex and frequently changing application scenarios. In addition, flexible cables have a long service life, with a typical service life of more than 10 years.

Although flexible cables have many advantages, ordinary cables still have advantages in certain application scenarios. For example, in low-frequency application scenarios such as fixed installation, ordinary cables have lower costs and higher transmission stability. In addition, since ordinary cables do not need to withstand frequent bending and twisting, their service life is relatively long.

Flexible cables and ordinary cables each have their own applicable scenarios and advantages. When choosing cables, it is necessary to consider various factors comprehensively, such as the number of conductors, conductor materials, insulation materials, sheath materials, voltage level, temperature range, cable length, and bending radius, to ensure that the selected cable can meet the requirements and has good transmission performance and reliability.

In summary, flexible cables are a high-performance and widely used cable product, with long service life, good flexibility, small bending radius, and other characteristics that play an important role in modern industrial production. With the development and continuous updating of technology, they will provide more advanced, efficient and reliable guarantees for more fields.