PVC cable is a commonly used wire and cable product, whose main material is polyvinyl chloride (PVC) resin. PVC cables have a wide range of applications in various fields such as industry, construction, transportation, and energy. This article will provide a detailed introduction to PVC cables from the following aspects.

What is PVC cable?

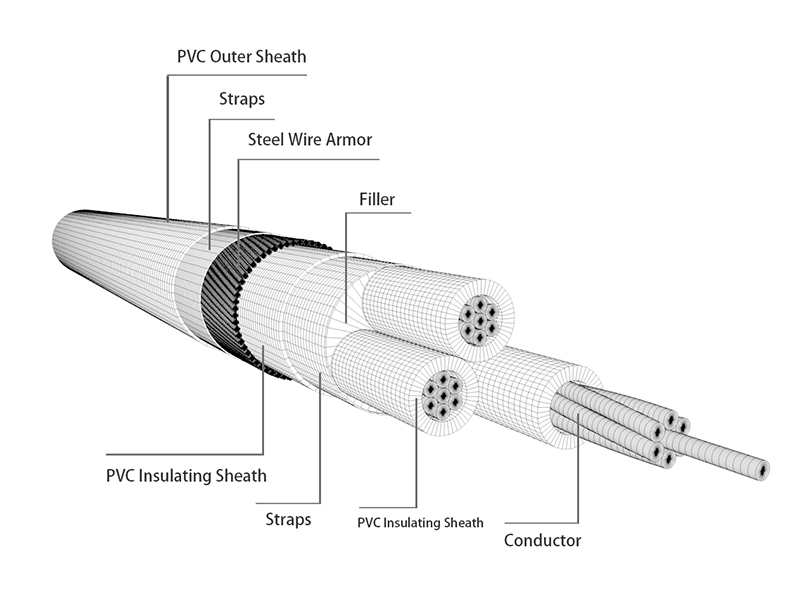

PVC cable is a cable made of polyvinyl chloride (PVC) resin as the main material. Due to the excellent heat resistance, insulation, and physical mechanical properties of PVC, it is widely used in various cables. PVC cables can be divided into two types: sheath level and insulation level, of which the sheath level requires good heat resistance and the insulation level requires good insulation.

Main features of PVC cable

- Excellent mechanical properties

PVC cable has good mechanical properties such as tensile strength, compressive strength and bending strength, and can meet the requirements of stretching, extrusion and bending under various conditions of use. - Excellent electrical properties

PVC cables have high dielectric constant and insulation resistance, which can effectively protect conductors and ensure the stability and reliability of transmitted signals. - Good chemical resistance

PVC cables have high acid and alkali resistance and high corrosion resistance, and can be used in various harsh environmental conditions, such as oil pollution, water vapor, odor and other environments. - Easy to process and form

PVC cable material has good processing and forming properties, and can be manufactured into cable products of various shapes and specifications through extrusion, injection molding and other processes.

Application field of PVC cable

PVC cables are widely used, including construction, industry, transportation, energy and other fields. The following are the main applications of PVC cables in various fields:

- Construction field

In the field of construction, PVC cables are mainly used for power supply of electrical circuits inside buildings. For example, PVC cables are used in walls, roofs, floors, etc. - Industrial field

PVC cables are mainly used in the industrial field for electrical connection of various machinery and equipment, electrical devices, such as motor wiring, control systems and signal transmission. - Transportation

In the field of transportation, PVC cables are mainly used for power supply of electrical lines in transportation projects such as subways, highways, and tunnels. - Energy sector

In the energy field, PVC cables are mainly used for electrical connection of various power generation facilities, substations and other electrical equipment.

Care and maintenance of PVC cables

PVC cables need to pay attention to the following points during use:

Keep the cable clean and dry to avoid moisture and pollution;

Avoid excessive bending and pulling of cables;

Avoid long-term excessive current of the cable;

Regularly check the connections and joints of the cables and the state of the insulation.

Manufacturing process of PVC cable

- Preparation of PVC compound: mix raw materials such as PVC resin, additives and fillers through a mixer to obtain PVC compound.

- Extrusion molding: Put the PVC mixture into the extruder, and extrude the PVC mixture into shape through the action of the extruder barrel and the screw extrusion head.

- Cooling and solidification: Cool the extruded PVC cable through a cooling machine to make it solidify quickly, and at the same time stretch it through a stretching machine to make its surface smooth.

- Inspection and packaging: inspect the cooled and solidified PVC cables, and package the products that meet the requirements.

How to choose PVC cable

- Determine the purpose of the PVC cable

Before selecting a PVC cable, it is first necessary to clarify the purpose of the cable. Is it a power connection as an electrical device? Or for data transfer? Different purposes require the use of PVC cables with different specifications and characteristics. Therefore, understanding the specific usage scenarios is very helpful for choosing the right PVC cable. - Check the specifications of the PVC cable

The specifications of PVC cables include conductor diameter, cross-sectional area, rated voltage, insulation thickness, shielding type, etc. By understanding these specifications, you can judge whether the PVC cable meets your needs. For example, when selecting wires, it is necessary to pay attention to whether the cross-sectional area of the conductor is sufficient, and when selecting cables, it is necessary to pay attention to whether the rated voltage meets actual needs. - Consider the material of PVC cable

PVC cable is composed of polyvinyl chloride resin, stabilizer, plasticizer, filler, lubricant and so on. The insulation material of PVC cable has a great influence on its service life, heat resistance quality and tensile strength. Therefore, when selecting PVC cables, it is necessary to pay attention to its material quality and characteristics, and choose cables made of materials with good insulation, fire resistance, and anti-aging properties. - Pay attention to the quality certification of PVC cables

When selecting PVC cables, you need to pay attention to whether they have passed relevant quality certifications, such as ISO9001, CCC and other certifications. These certifications can ensure that the quality and performance of PVC cables meet relevant standards, with high reliability and safety. - Choose a reputable producer

When selecting PVC cables, it is necessary to choose a reputable manufacturer, which can ensure that the quality and performance of PVC cables meet the standard requirements. At the same time, when communicating with the manufacturer, it is also necessary to understand the manufacturer's manufacturing process and after-sales service in detail, so as to ensure that effective technical support and services can be obtained in a timely manner after purchasing PVC cables.

Conclusion

PVC cable is a cable widely used in various fields. It has the advantages of good physical and mechanical properties, chemical resistance, insulation and heat resistance, and can be adjusted and improved according to needs during the manufacturing process to meet the needs of different users. demand. Therefore, when using and maintaining PVC cables, you need to pay attention to the above points to ensure their service life and safety.