When it comes to electrical wiring, there are a lot of factors to consider. One of the most important is deciding what type of conductor to use. Some might assume that aluminum is always better than Copper, but that's only sometimes the case. So let's take a look at the pros and cons of each type of conductor to see which one is right for your project.

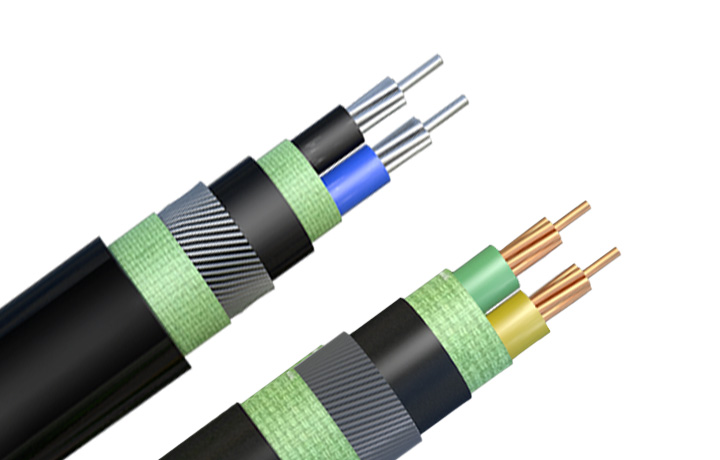

The properties of copper conductor

As a conductor of electricity, Copper is an essential component in a wide range of electrical devices and systems. Its high electrical conductivity and low resistance make it ideal for applications such as electrical wiring and circuit boards.

Copper is also highly corrosion-resistant, which helps to ensure the longevity of electrical components and systems. In addition, Copper conducts heat well, making it an ideal material for heatsinks and other thermal management applications. With its unique properties, Copper is essential for electrical engineers and technicians.

The properties of aluminium conductor

The aluminium conductor is one of the most popular choices for electrical wiring, thanks to its many advantageous properties. It is an excellent conductor of electricity and is also very lightweight and corrosion-resistant.

In addition, the aluminium conductor is easy to work with, making it a good choice for various applications. And because it is non-toxic, it can be used in a wide range of settings, including in food preparation and handling. With so many benefits, it's no wonder that aluminium conductor is one of the most popular choices for electrical wiring.

How they are used in electrical wiring?

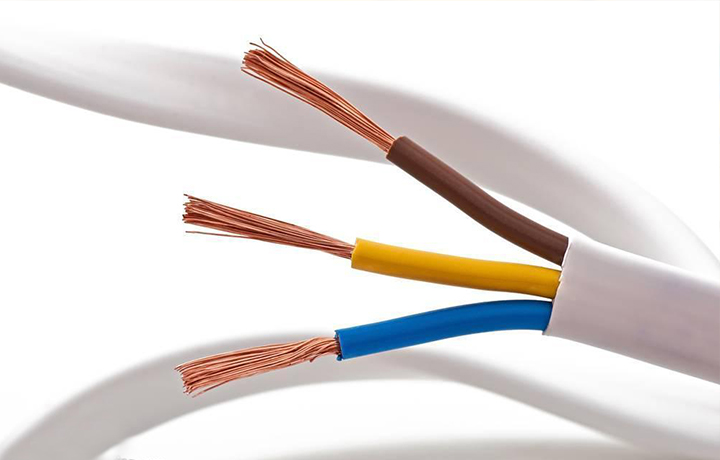

One of the most important choices when it comes to electrical wiring is what kind of conductor to use. Aluminium and Copper are two of the most popular materials, but each has its own advantages and disadvantages. Aluminium conductor is less expensive and lighter than Copper, making it easier to work with.

However, it is also more prone to corrosion, which can cause electrical problems over time. On the other hand, a copper conductor is more durable and expensive. As a result, it is often used in high-end applications where reliability is essential. Ultimately, the best choice for electrical wiring depends on the project's specific needs.

Advantages and disadvantages of Copper and aluminum conductor

When it comes to electrical conductors, two primary materials are used: aluminium and Copper. Each of these materials has its own advantages and disadvantages, so it's important to choose the right one for your needs. For example, Copper is a highly conductive metal, which makes it ideal for electrical applications.

However, it is also quite expensive, so there may be better choices for large-scale projects. Aluminum, on the other hand, is much cheaper but less conductive. This makes it better suited for applications where cost is a major concern. Therefore, when choosing between aluminium and copper conductors, it's essential to weigh all the factors and choose the best material that suits your needs.

Which is better for your needs?

Aluminium conductor and copper conductor both have their pros and cons. It really depends on your needs as to which one is better for you. Aluminium conductor is cheaper than the copper conductor, but it is less durable. Copper conductor is more expensive but it is more durable. Aluminium conductor is also more flexible than copper conductor. Copper conductor conducts electricity better than the aluminum conductor.

It all depends on your needs as to which one would be better for you. If you need a cheap and flexible conductor, then an aluminium conductor would be better for you. If you need a more expensive conductor that conducts electricity better, then copper conductor would be better for you.

The benefits of Copper over aluminium

Copper has been used in electrical wiring for centuries, and it is only recently that aluminium has begun to be used as an alternative. However, there are several reasons why Copper is still the preferred material for electrical wiring. First of all, Copper is a much better conductor of electricity than aluminium. This means that less energy is lost as heat when it is used to carry an electrical current.

In addition, Copper is much tougher than aluminium and it is less likely to be damaged by accidental knocks or vibrations. Finally, Copper is entirely recyclable, while aluminium can only be recycled a limited number of times before it becomes too degraded to be useful. For all these reasons, Copper remains the material of choice for electrical wiring.

Copper conductor installation

The installation of copper conductors is a critical step in the construction of electrical power systems. Copper is an excellent conductor of electricity and has a high resistance to corrosion, making it ideal for use in power lines and other electrical applications.

The installation of copper conductors requires precise planning and execution, as even a small mistake can result in serious damage to the electrical system. The first step in the installation process is to select the type of copper conductor that will be used. There are a variety of copper conductor types available, each with its own advantages and disadvantages.

Once the type of conductor has been selected, the next step is to determine the route that the conductor will take. The route must be carefully planned to avoid any obstacles that could damage the conductor. After the route has been determined, the next step is to install the conductor. This process includes attaching the conductor to support structures and running it through cable trays or ducts.

Finally, all connections must be checked to ensure that they are secure and that there are no gaps or damaged areas. Once the installation is complete, the new electrical system will be ready to provide power to homes and businesses.

Aluminium conductor installation

Aluminium conductors are an increasingly popular choice for electrical installations, due to their high conductivity and resistance to corrosion. However, installing aluminium conductors can be a challenging process, as they require specialised equipment and techniques.

The first step is to prepare the cable for installation, which involves stripping away the insulation and ensuring that the ends are clean and free of debris. Next, lugs or clamps must attach the conductor to the distribution panel. Once the conductor is in place, it must be appropriately secured to prevent movement or vibration.

Finally, the installation must be tested for voltage drop and current carrying capacity. With proper preparation and care, installing aluminium conductors can be a safe and efficient way to upgrade your electrical system.

Copper vs aluminium cost

When it comes to electrical conductivity, there is no clear winner between Copper and aluminium. Copper is an excellent conductor of electricity, but it is also expensive and susceptible to corrosion. Aluminium, on the other hand, is cheaper and more resistant to corrosion, but it is not quite as good a conductor as Copper. So, which one is the better choice? The answer depends on the specific application.

For example, Copper is often used in high-voltage applications because it can carry more current than aluminium. On the other hand, aluminium is often used in low-voltage applications because it is less likely to cause electrical fires. Ultimately, the decision between Copper and aluminium comes down to cost and performance.

Which is better for you and your needs?

Copper has been used in electrical applications for centuries, and it is easy to see why. This naturally occurring element is highly conductive and has a relatively low resistance, making it ideal for use in electrical wiring. However, Copper is also quite expensive, which is why aluminium has become increasingly popular in recent years.

Aluminium is much cheaper than Copper and still offers decent conductivity and low resistance. However, there are some drawbacks to using aluminium. First of all, it is not as strong as Copper, which means that it needs to be thicker in order to carry the same amount of current. This can make aluminium wiring more difficult to work with.

Additionally, aluminium oxidizes quickly when exposed to air, which can cause problems with electrical connections over time. For these reasons, Copper remains the preferred choice for many electrical applications. However, if cost is a factor, aluminium may be a viable option.

Conclusion

Copper is the better conductor of electricity as it has a higher conductivity rating and lower resistance. This means that Copper can handle more current than aluminium, making it ideal for electrical applications.

Copper is also less likely to corrode than aluminium, which makes it a more durable choice in harsh environments. While aluminium conductors are cheaper and lighter than Copper, they are not as effective at carrying electrical current and are more susceptible to corrosion. For these reasons, Copper is the preferred choice for most electrical applications.