This standard applies to materials, constructions, and testing of 5000 volt to 46,000 volt shieldedcrosslinked polyethylene, and ethylene propylene rubber insulated wires and cables which are used for the transmission and distribution of electrical energy for normal conditions of installation and service,either indoors, outdoors, aerial, underground, or submarine.

Features

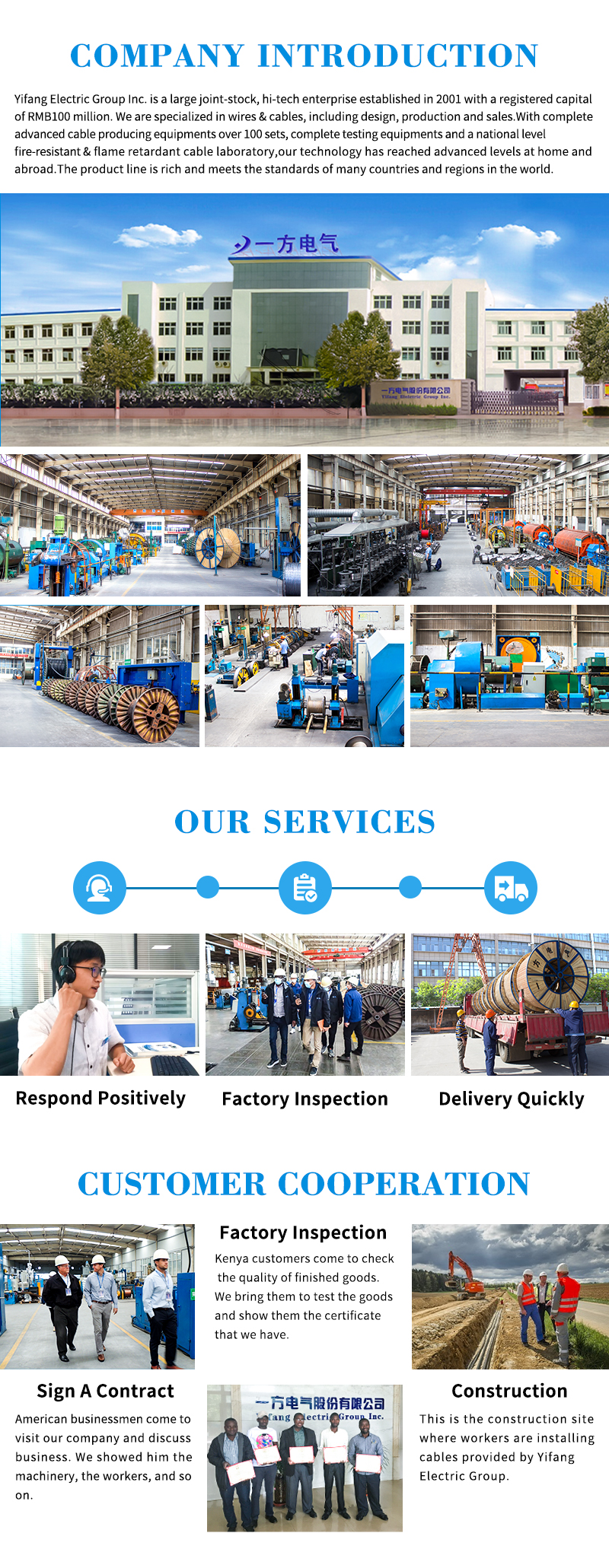

Medium voltage cables refer to power cables with a rated voltage between 6kV and 35kV, which are widely used in power distribution and power generation networks. Medium voltage cables have good insulation performance, mechanical strength, heat resistance and environmental corrosion resistance, can adapt to various terrain and climatic conditions, and improve power supply reliability and safety.

Among them, XLPE medium-voltage cables are currently the most commonly used type, occupying a dominant position in the market. XLPE medium voltage cables have excellent heat resistance, aging resistance, chemical corrosion resistance and water tree aging resistance, can withstand high working temperature and overload temperature, and prolong the service life.

Application

Medium-voltage cables refer to AC power cables with a rated voltage between 3.6/6kV~26/35kV, which are mainly used to transmit and distribute medium-voltage electric energy. Medium-voltage cables have the advantages of simple structure, low manufacturing cost, convenient laying, and simple maintenance. They are widely used in various fields of the national economy, especially in urban distribution networks, industrial and mining enterprises, and new energy development.

Construction

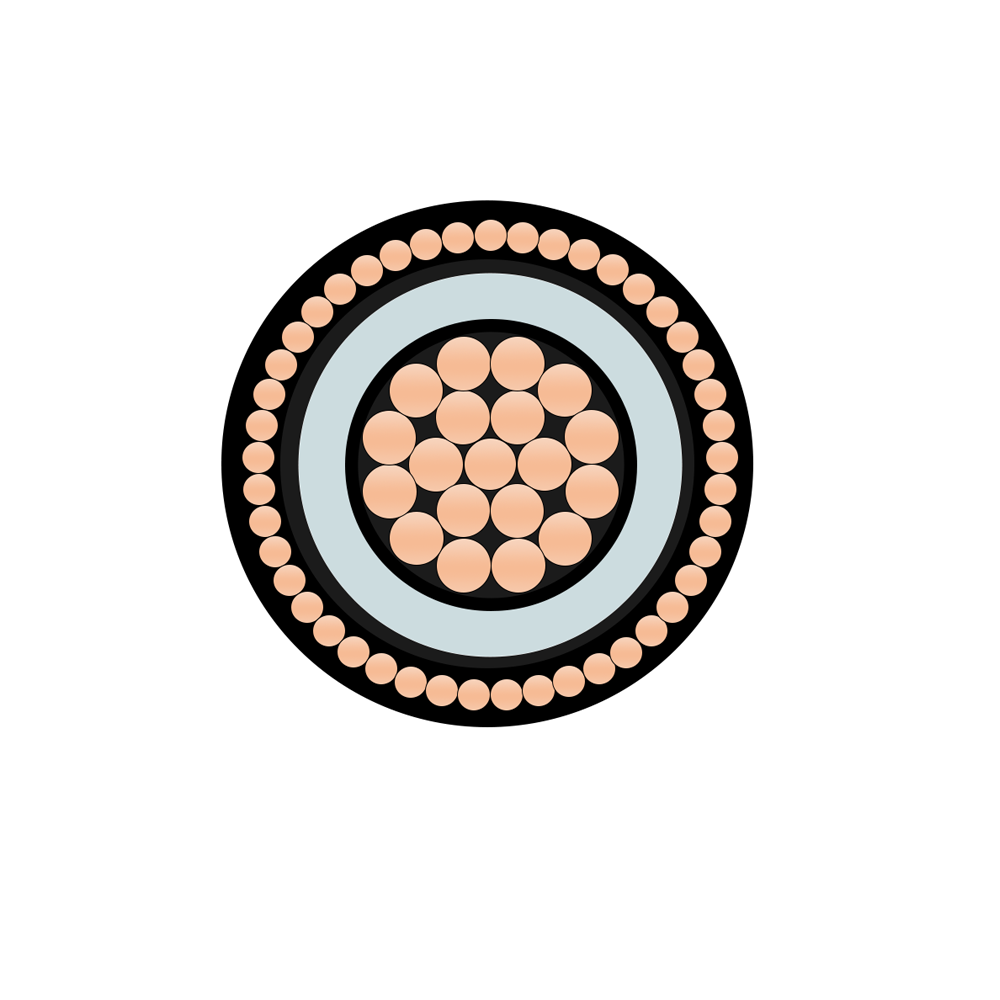

1.Conductor

Conductors are generally made of copper or aluminum.

2.Insulation

Insulation is generally made of materials such as XLPE,EPR or PVC, with high withstand voltage test and power frequency withstand test level.

3.Metal shielding

Metal shielding is generally made of materials such as concentric copper wire or copper tape, applied individually on each core or collectively on all cores.

4.Sheath

The sheath is generally made of materials such as PVC, PE or LSZH, which are extruded on the metal shield.

Medium-voltage power cables have shielding and sheathing, and non-magnetic armoring can be used under necessary conditions. Refer to the figure below for the structure of conventional cables.

Performance

| Type | Rated voltage kV | Thickness mm |

| 10B-A | 8.7/15 | 4.5 |

| 12/20 | 5.5 | |

| 18/30 | 8.0 | |

| 20.8/36 | 8.8 | |

| 10B-B | 8.7/15 | 3.6 |

| 10B-C | 20.8/36 | 6.0 |

Type 10B-A

The thickness in any place shall not be below 90 % of the nominal value by more 0,10 mm.

Type 10B-B

The thickness shall not, at any point, be less than 3,60 mm.

Type 10B-C

The thickness shall not, at any point, be lessthan 5.30 mm.