Aerial insulated cables have a voltage of 0.6/1KV and are overhead wires with insulation. Conductors generally use AAC, AAAC stranded wire. The insulating material is 90°C XLPE.

Features

1.Low operating cost

The construction cost, operating cost and maintenance cost of overhead insulated cables are lower than those of underground cables, because it does not require underground laying, excavation, backfilling, etc., and is easier to repair and replace

2.Easy troubleshooting

Faults on overhead insulated cables are easy to find and locate, which can be repaired more quickly to ensure the reliability of power supply, while underground cables may be troublesome to locate when faults occur, and the repair time will be relatively long

3.Wide range of application

Overhead insulated cables are suitable for various harsh environments, such as strong winds, lightning strikes, etc., while underground cables are greatly affected by geological conditions and the environment, and may not be suitable for all areas and application scenarios.

4.Fast construction speed

Aerial insulated cables can be erected directly in the sky without being restricted by terrain and buildings, so the construction speed is faster.

Application

1.Power transmission

The power generated by the power plant is transmitted to the substations in various cities and regions through overhead insulated wires

2.Power distribution

Converting high-voltage electrical energy in substations to low-voltage electrical energy and delivering it to places such as homes, commercial buildings, and industrial facilities for human consumption.

3.Power supply to electric railways

Overhead insulated wires are often used to supply power to electrified railways such as trams and subways.

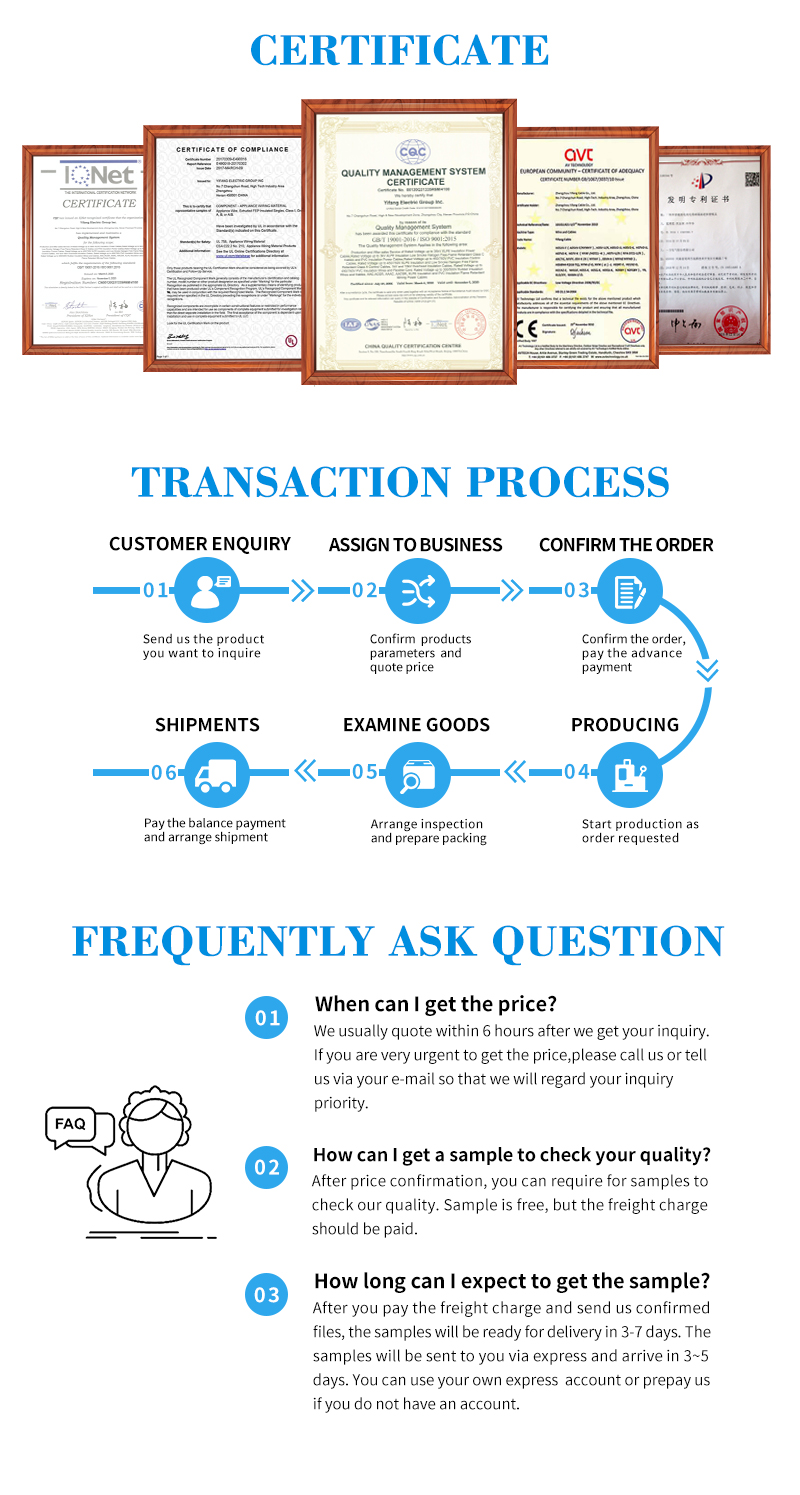

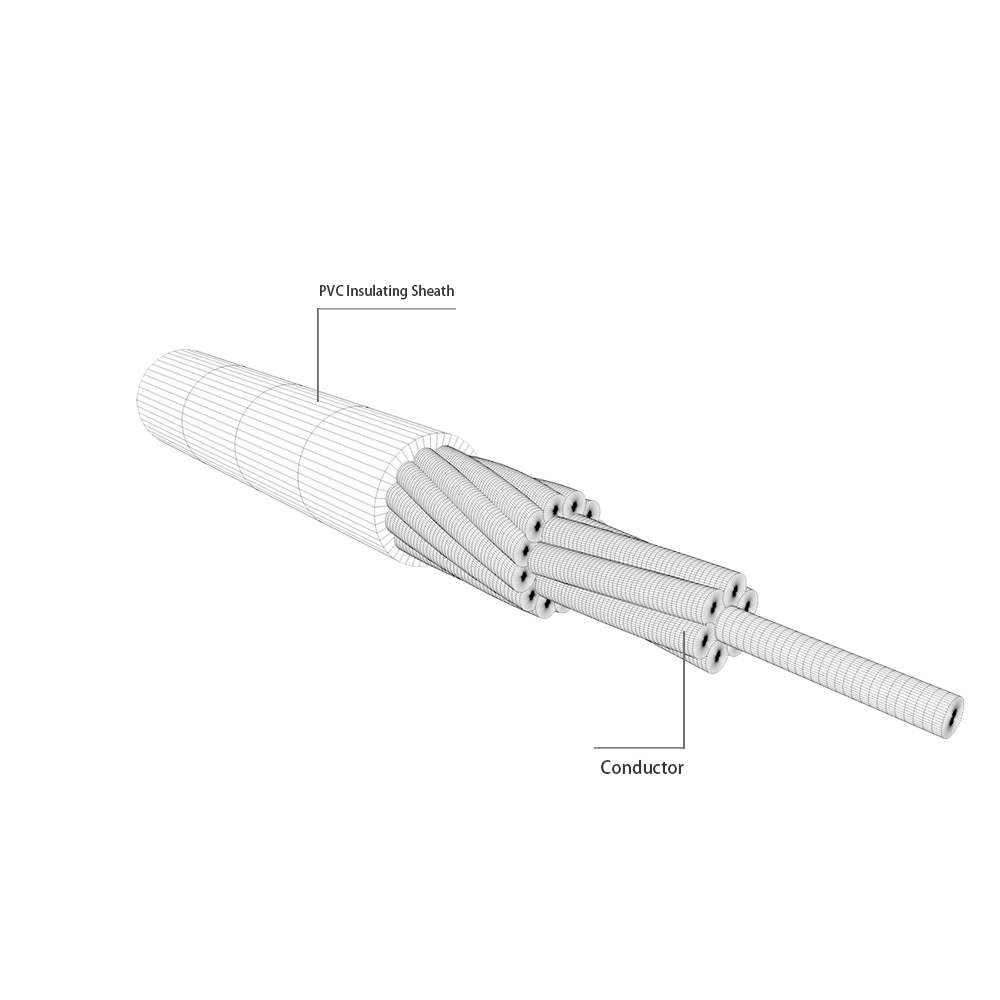

Construction

1.Conductor

The wire core has a circular cross-section. Bundled conductors with or without supporting cores, auxiliary cores or grounding cores or a combination of the above cores. The outermost stranding direction of the conductor is left. In ABC cables, steel-cored aluminum stranded wires or Aluminum alloy stranded wires make conductors.

2.Insulation

The insulation layer of ABC cables is usually made of cross-linked polyethylene material, which has excellent pressure resistance and insulation properties. The thickness of the insulating layer can be designed and adjusted according to the use environment and electrical requirements

3.Cabling

Multi-core cables (multiple-conductors) should be cabled, the cabled direction is right, and the cabled pitch ratio is 60 times.

Performance

| Nominal cross-section | Apporx.dia. of conductor | Apporx.outer dia. of cable | Approx. weight | Min. breaking load | Max. DC resistance at 20℃ | Current rating in air at 40℃ |

| mm2 | mm | mm | kg/km | kN | Ohm/km | A |

| 10 | 3.8 | 5.9 | 104 | 3.47 | 1.906 | 58 |

| 16 | 4.8 | 7.3 | 160 | 5.49 | 1.198 | 78 |

| 25 | 6.01 | 8.5 | 243 | 8.47 | 0.749 | 105 |

| 35 | 7.06 | 9.9 | 338 | 11.73 | 0.540 | 125 |

| 50 | 8.18 | 11.1 | 451 | 16.50 | 0.399 | 155 |

| 70 | 9.88 | 12.8 | 643 | 23.46 | 0.276 | 195 |

| 95 | 11.6 | 14.9 | 882 | 31.76 | 0.199 | 240 |

| 120 | 13.09 | 16.4 | 1110 | 39.91 | 0.158 | 280 |

| 150 | 14.3 | 18 | 1369 | 49.51 | 0.128 | 320 |

| 185 | 16.2 | 20.3 | 1713 | 61.85 | 0.1021 | 370 |

| 240 | 18.61 | 23.1 | 2272 | 79.82 | 0.0777 | 440 |