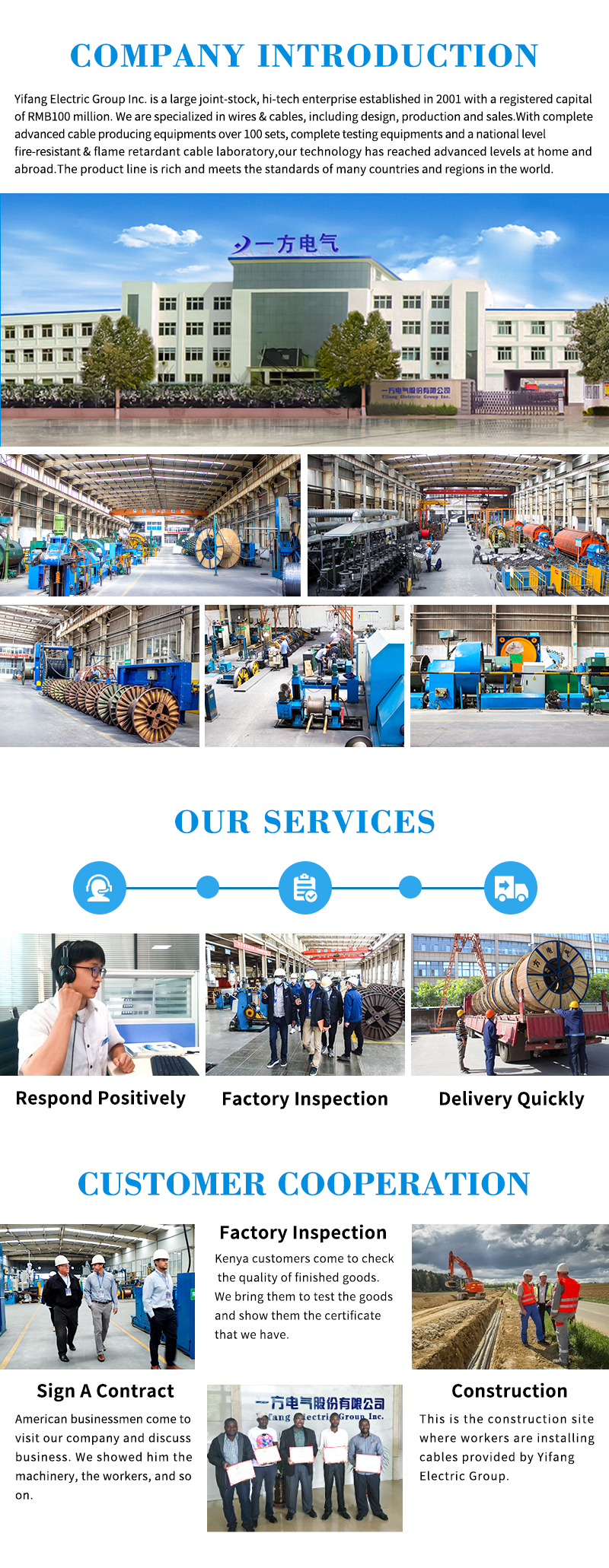

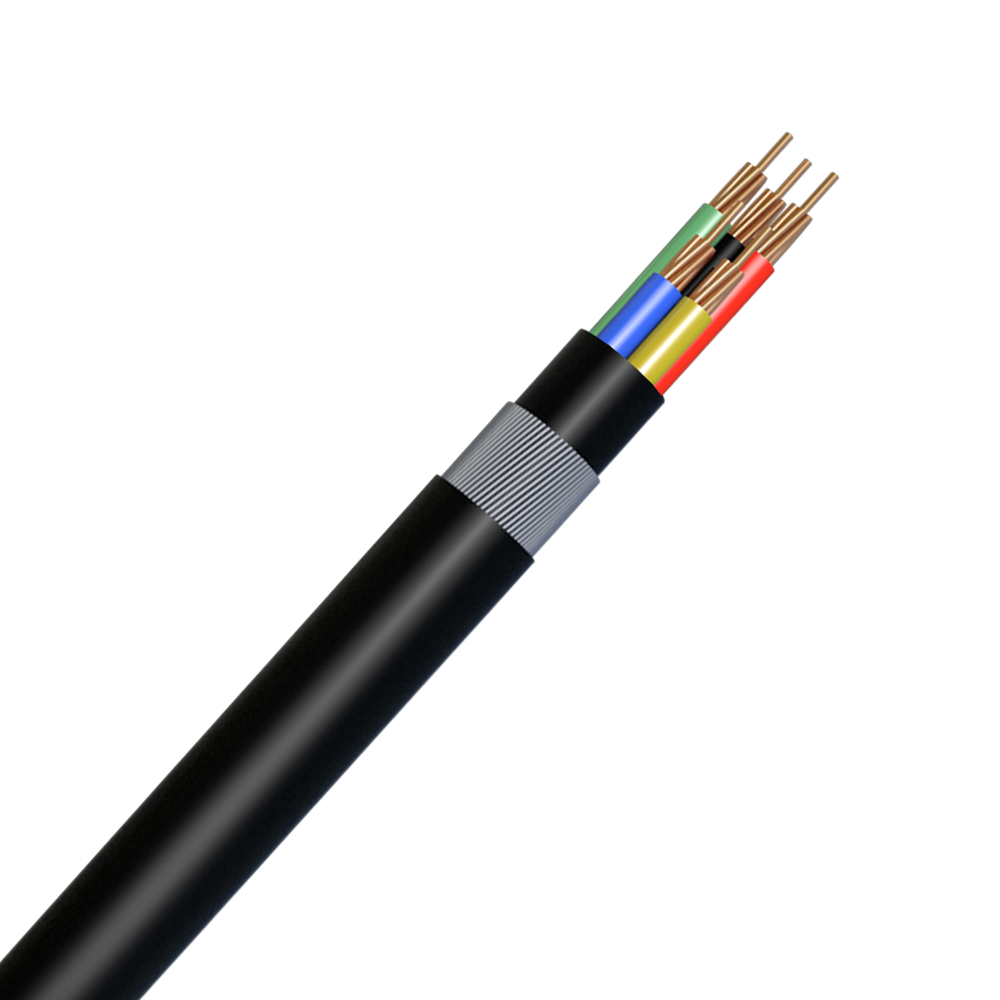

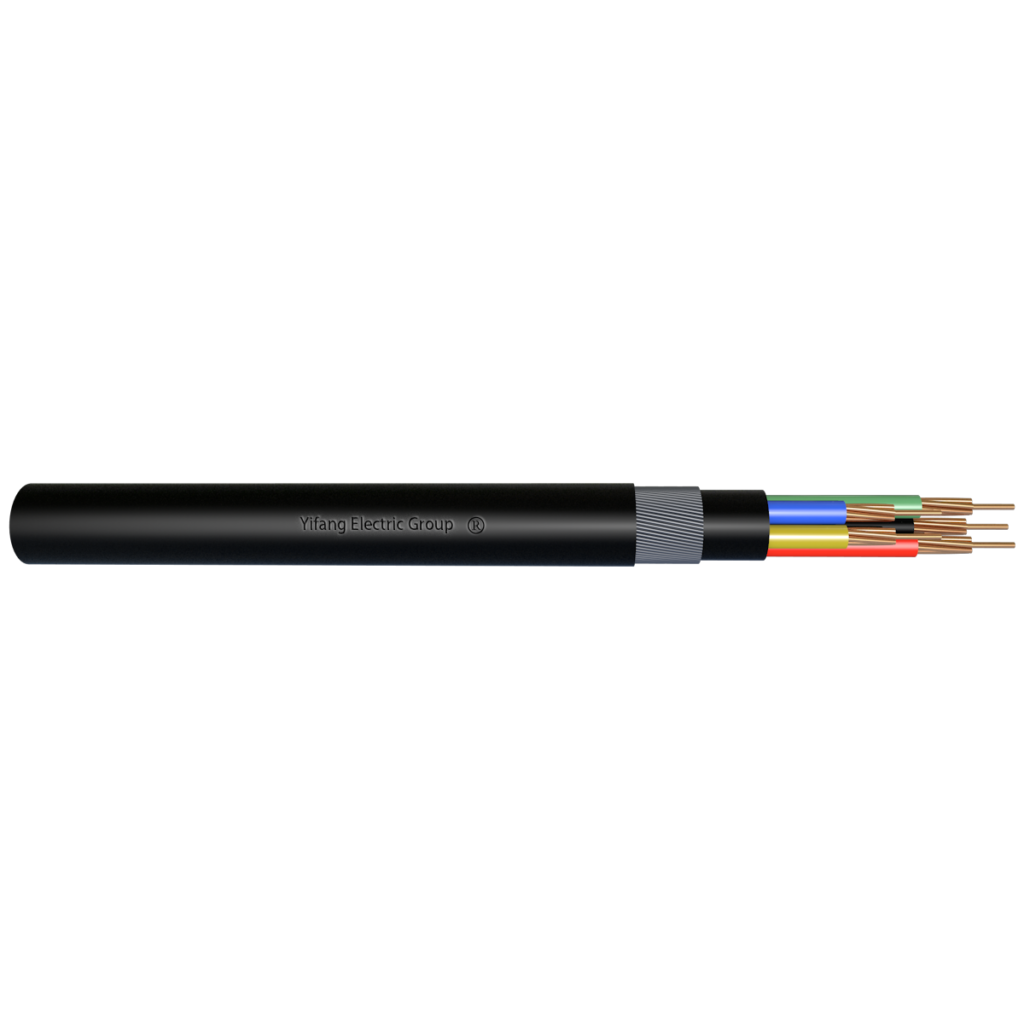

0.6/1KV PVC-insulated cables are now a common product in power systems. They have sturdy constructions. The cross-section range is wide, and different cable specifications can be chosen depending on the system being utilized, such as three-phase four-wire system or three-phase five-wire system. The conductor material can be selected from aluminum, copper, aluminum alloy and other materials. It can be manufactured according to the standards of different countries according to the needs of users. Its main performance parameters are as follows

- AC rated voltage (U0/U): 0.6/1kV.

- The maximum working temperature of polyethylene gas should not exceed 70C.

- Minimum ambient temperature: -15C.

- The temperature of the electric performance installation should not be lower than 0"C.

- The allowable bending radius of the cable is specified in Table 1.

| item | single core cableno armor | single core cablearmor | three-core cableno armor | three-core cablearmor |

| Cable minimum bending radius during installation | 20D | 15D | 15D | 12D |

| The minimum bend radius of the electrical terminal near the connection box and the terminal (but the bending should be carefully controlled, such as using a formed guide plate) | 15D | 12D | 12D | 10D |

This standard specifies the structure, size and experimental requirements of PVC insulated power cables with rated voltage U0/U of 0.6/1kv, with (3G-1 type) or without (3G-2 type) concentric conductors, without armor.

Features

The product performs well in terms of electrical characteristics and chemical resistance, including acid resistance, alkali resistance, and resistance to organic solvents. In other words, the cable can be laid with no restriction on head drop in any head drop circumstance, including vertically, wherever the product is laid.

Application

This product is appropriate for industrial devices, distribution networks, and other industries. It has a rated voltage of 0.6/1 kV and is suitable for fixed laying on electricity transmission and distribution lines with AC 50Hz. The transmission of electric electricity is the major purpose. This product should only be used in situations with typical conditions; it is not appropriate for use in nuclear power plants, airborne, undersea, marine, or other unique environments.

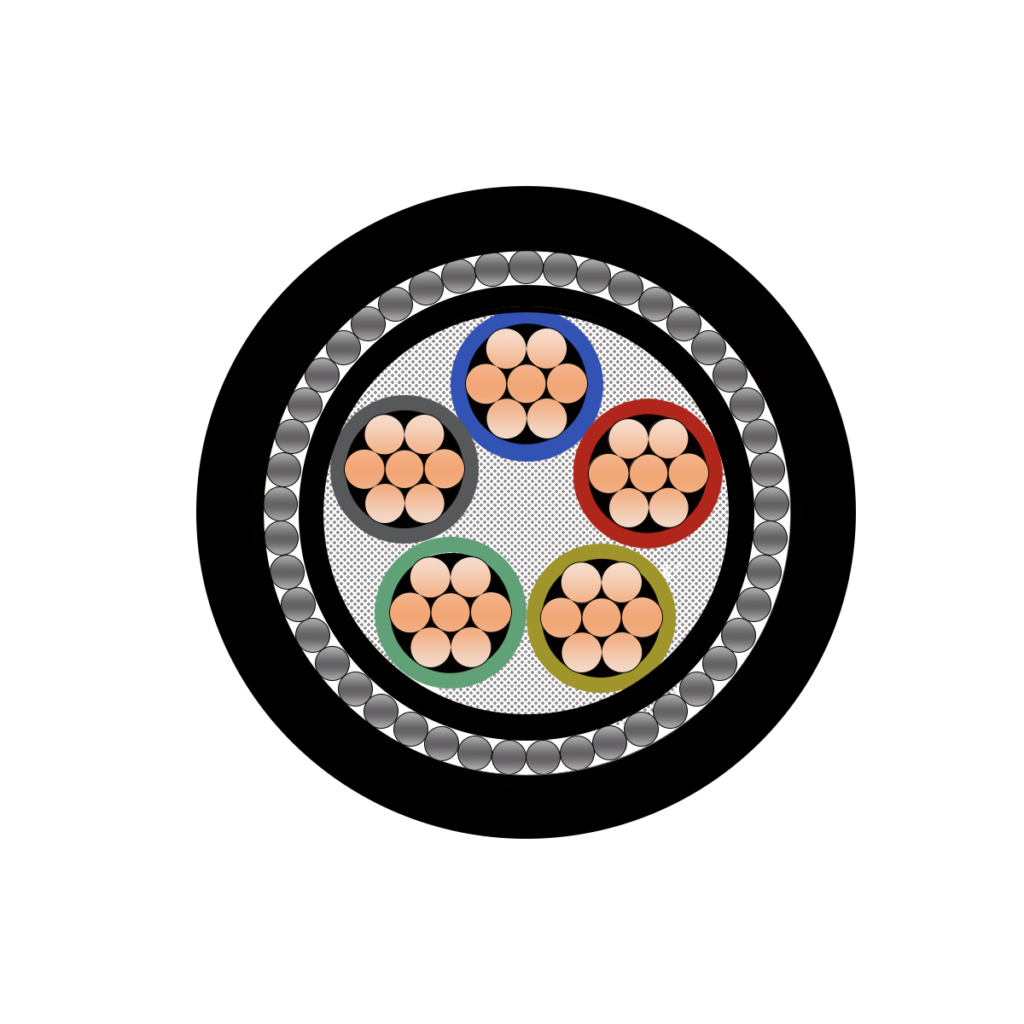

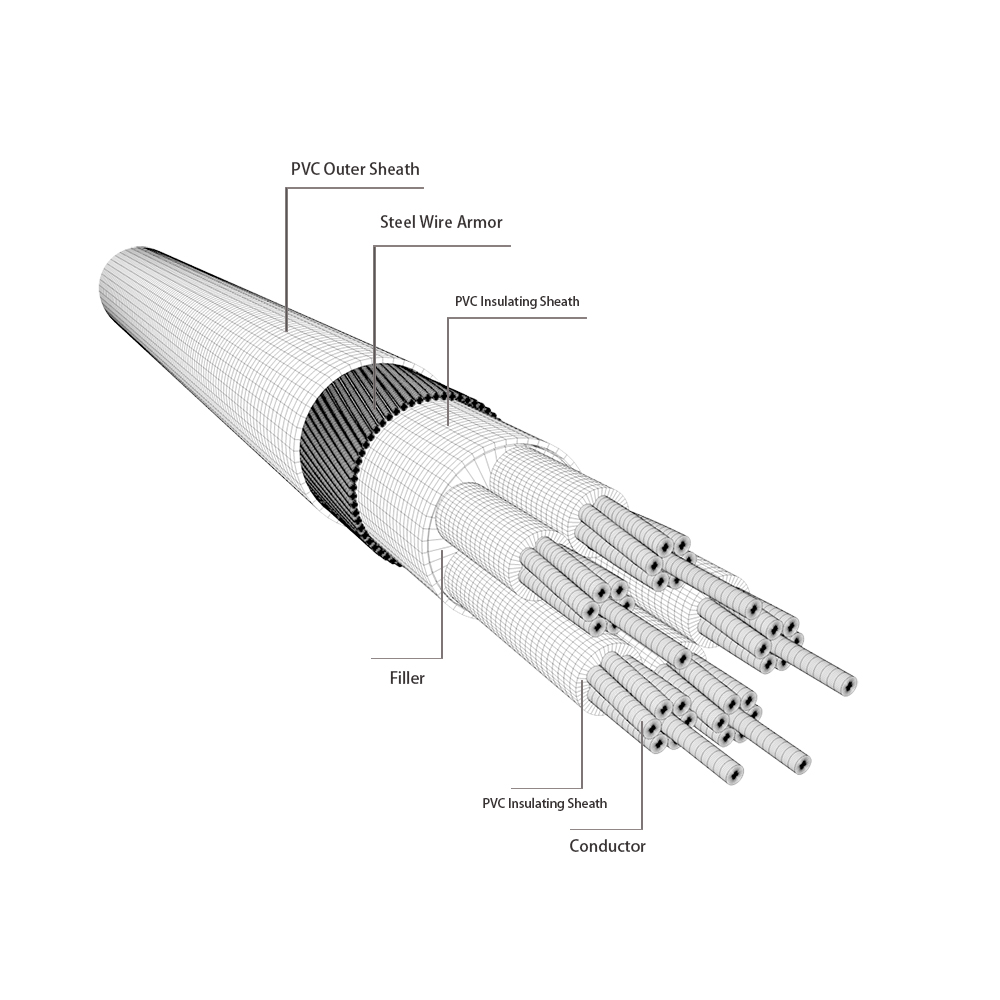

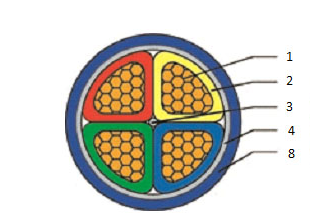

Construction

Performance

| Conductor Nominal Section | Insulation Thickness | Insulation Thickness | Insulation Thickness |

| mm2 | PVC | XLPE and HEPR | EPR |

| 1.5 and 2.5 | 0.8 | 0.7 | 1.0 |

| 4 and 6 | 1.0 | 0.7 | 1.0 |

| 10 and 16 | 1.0 | 0.7 | 1.0 |

| 25 and 35 | 1.2 | 0.9 | 1.2 |

| 50 | 1.4 | 1.0 | 1.4 |

| 70 | 1.4 | 1.1 | 1.4 |

| 95 | 1.6 | 1.1 | 1.6 |

| 120 | 1.6 | 1.2 | 1.6 |

| 150 | 1.8 | 1.4 | 1.8 |

| 185 | 2.0 | 1.6 | 2.0 |

| 240 | 2.2 | 1.7 | 2.2 |

| 300 | 2.4 | 1.8 | 2.4 |

| 400 | 2.6 | 2.0 | 2.6 |

| 500 | 2.8 | 2.2 | 2.8 |

| 630 | 2.8 | 2.4 | 2.8 |

| 800 | 2.8 | 2.6 | 2.8 |

| 1000 | 3.0 | 2.8 | 3.0 |

| Number of cores Nominal section mm2 Conductor shape and type | Insulation Thickness nominal value mm | Insulation Thickness minimum value mm | Sheath thickness nominal value mm | outer diameter Minimum mm | outer diameter Maximum mm |

| 1x10RE 1x16RE 1x25RM 1x35RM 1x50RM 1x70RM 1x95RM 1x120RM 1x150RM 1x185RM 1x240RM 1x300RM 1x400RM 1x500RM | 1.0 1.0 1.2 1.2 1.4 1.4 1.6 1.6 1.8 2.0 2.2 2.4 2.6 2.8 | 0.80 0.80 0.98 0.98 1.16 1.16 1.34 1.34 1.52 1.70 1.88 2.06 2.24 2.42 | 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.9 2.0 2.1 | 10 11 12 13 15 16 18 20 22 24 27 29 33 37 | 12 13 15 16 18 19 21 23 26 28 31 33 38 42 |

| 3x16RE | 1 | 0.8 | 1.8 | 19 | 22 |

| 4x4RE 4x6RE 4x10RE 4x16RE 3x25RM/16RE 3x35SM/16RE 3x50SM/25RM 3x70SM/35SM 3x95SM/50SM 3x120SM/70SM 3x150SM/70SM 3x185SM/95SM 3x240SM/120SM | 1.0 1.0 1.0 1.0 1.2/1.0 1.2/1.0 1.4/1.2 1.4/1.2 1.6/1.4 1.6/1.4 1.8/1.4 2.0/1.6 2.2/1.6 | 0.80 0.80 0.80 0.80 0.98/0.80 0.98/0.80 1.16/0.98 1.16/0.98 1.34/1.16 1.34/1.16 1.52/1.16 1.70/1.34 1.88/1.34 | 1.8 1.8 1.8 1.8 1.8 1.8 1.9 2.0 2.2 2.3 2.4 2.6 2.8 | 14 15 17 20 24 24 28 31 37 40 44 49 56 | 18 19 21 24 30 31 35 38 44 48 52 57 64 |

| 5X4RE 5X6RE | 1.0 1.6 | 0.8 | 1.8 1.8 | 15 17 | 18 20 |