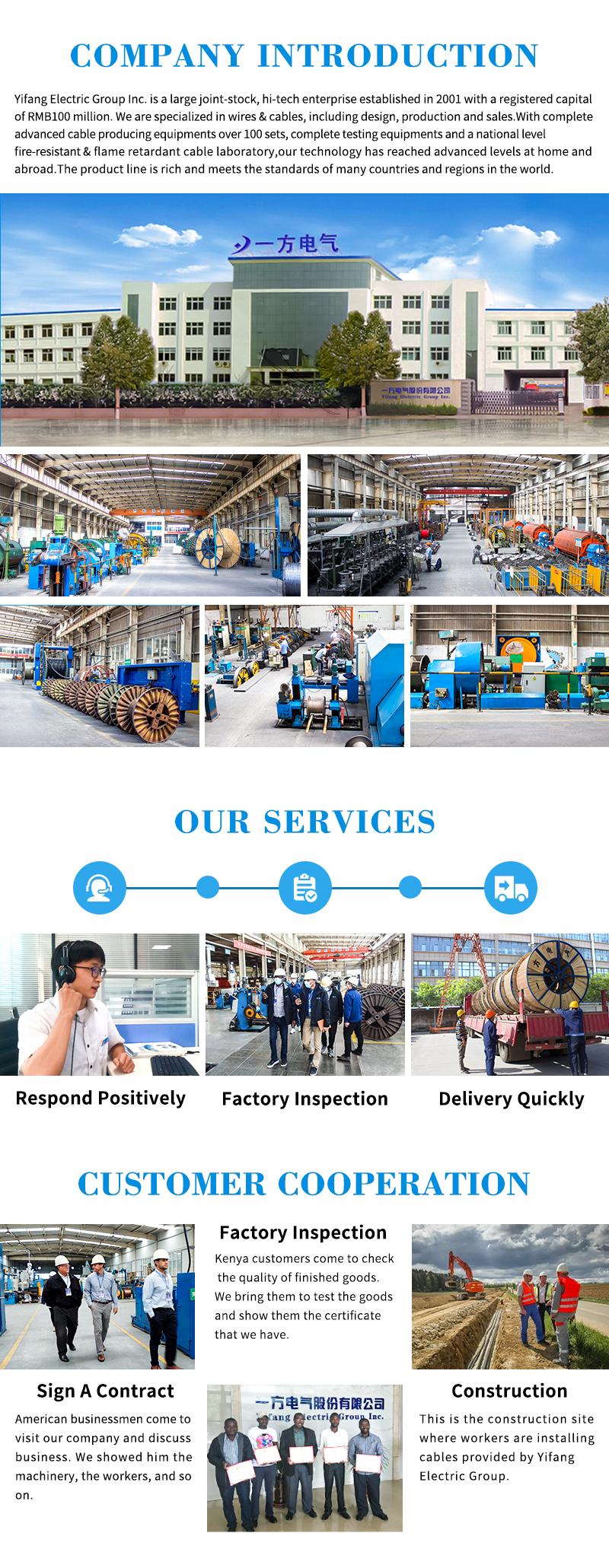

AAC conductor is also called aluminium stranded conductor.This British Standard applies to aluminium stranded conductors for overhead power transmission.Aluminium wires used in the construction of the conductor is material GIE in the H9 condition as specified in BS 26273.

Features

1.High conductivity

2.Exellent corrosion resistance

3.Good economic practicality

Application

These conductors can be used for a variety of voltages such as low, medium and high voltage. AAC is now also widely used in urban areas where short spans and high electrical conductivity are required.

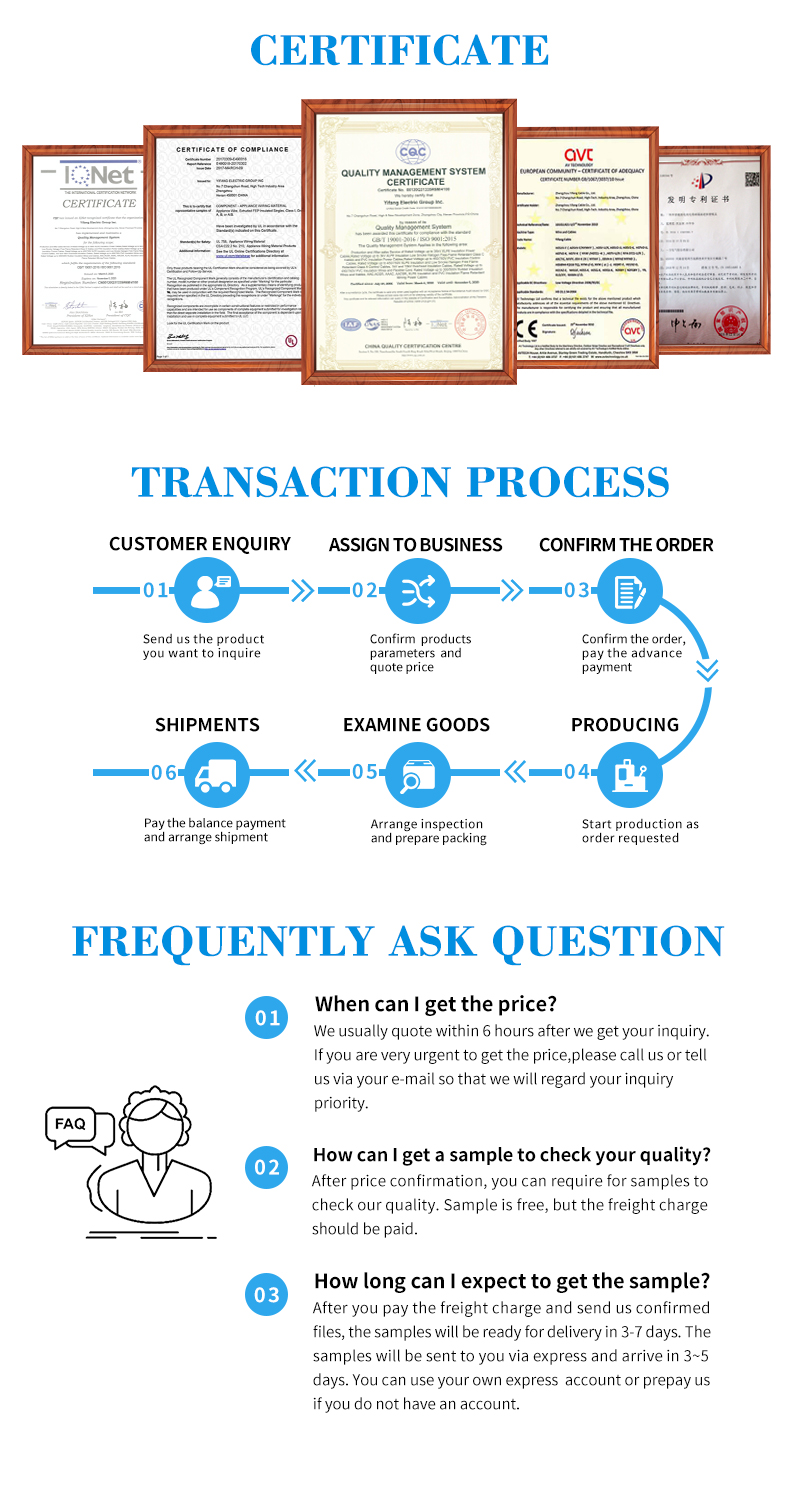

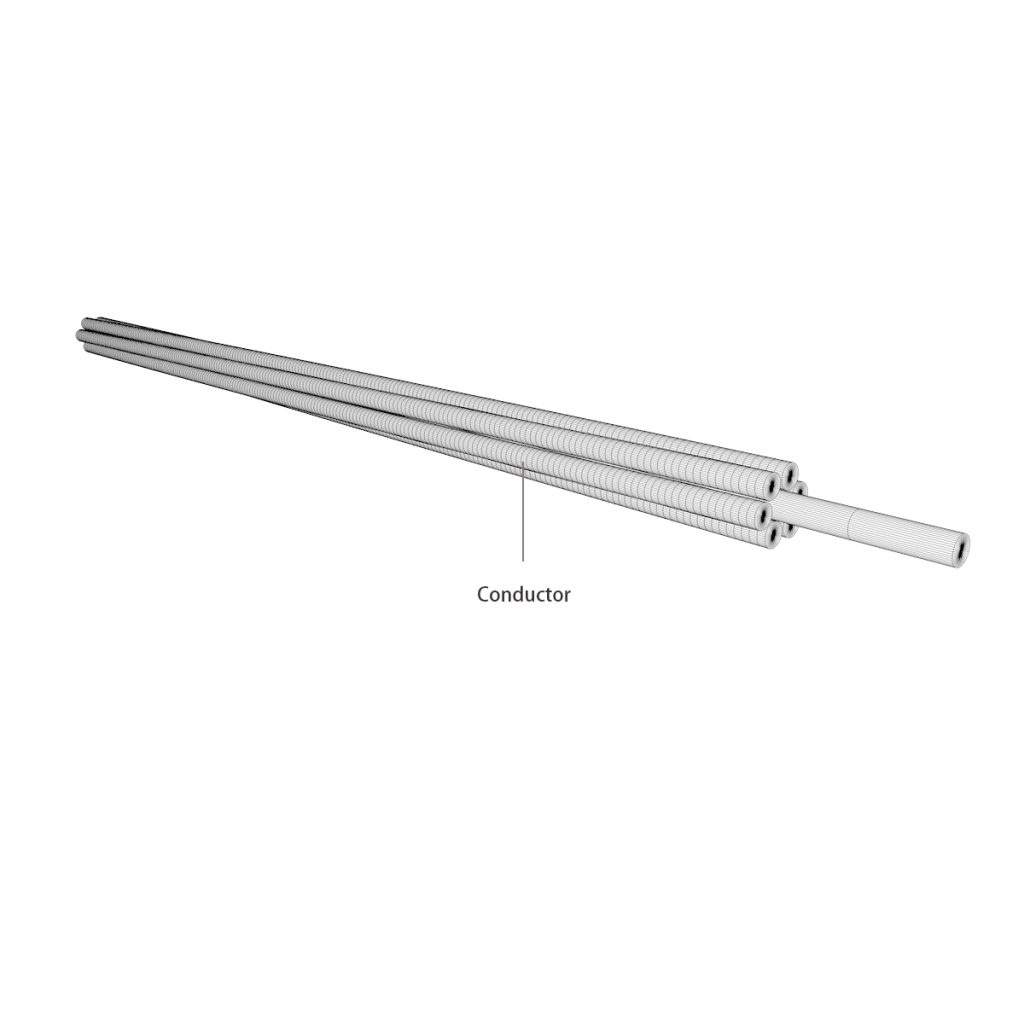

Construction

All aluminum conductors consist of one or more strands of aluminum wire.

Performance

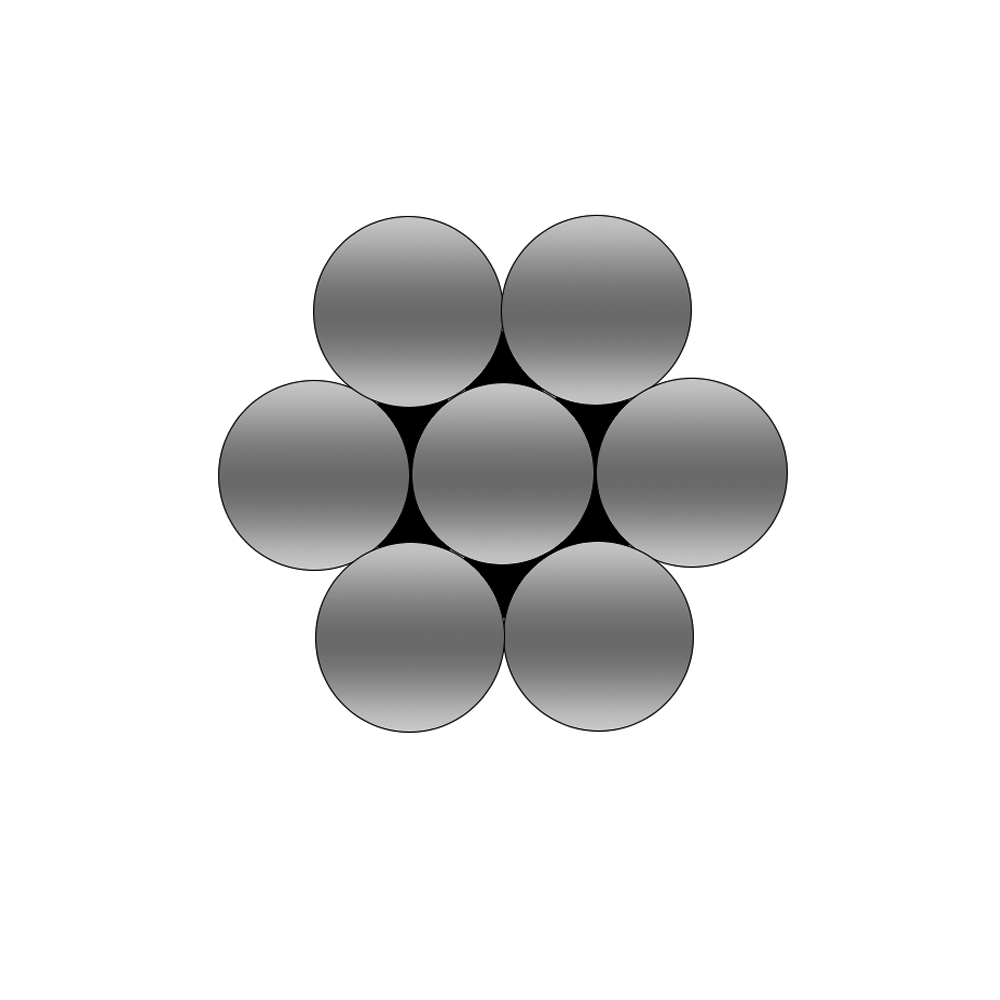

All Aluminum Conductor AAC–BS 215:

| Code Name | Nominal (mm2) | Stranding Nos &Wire Diameter (Nos / mm) | Overall Diameter (mm) | Sectional area (mm2) | Weight (kg/km) | Breaking Load (kN) | Max.DC Resistance at 20℃ (Ohm/km) | Current Rating (A) |

| Midge | 22 | 7/2.06 | 6.18 | 23.33 | 64 | 3.99 | 1.227 | 114 |

| Ant | 50 | 7/3.10 | 9.3 | 52.83 | 145 | 8.28 | 0.5419 | 181 |

| Fly | 60 | 7/3.40 | 10.2 | 63.55 | 174 | 9.9 | 0.4505 | 199 |

| Wasp | 100 | 7/4.39 | 13.17 | 106 | 290 | 16 | 0.2702 | 271 |

| Hornet | 150 | 19/3.25 | 16.25 | 157.6 | 434 | 25.7 | 0.1825 | 346 |

| Chafer | 200 | 19/3.78 | 18.9 | 213.2 | 587 | 32.4 | 0.1349 | 414 |

| Cockroach | 250 | 19/4.22 | 21.1 | 265.7 | 731 | 40.4 | 0.1083 | 470 |

| Butterfly | 300 | 19/4.65 | 23.25 | 322.7 | 888 | 48.75 | 0.08916 | 528 |

| Centipede | 400 | 37/3.78 | 26.46 | 415.2 | 1145 | 63.1 | 0.06944 | 619 |

Vedio