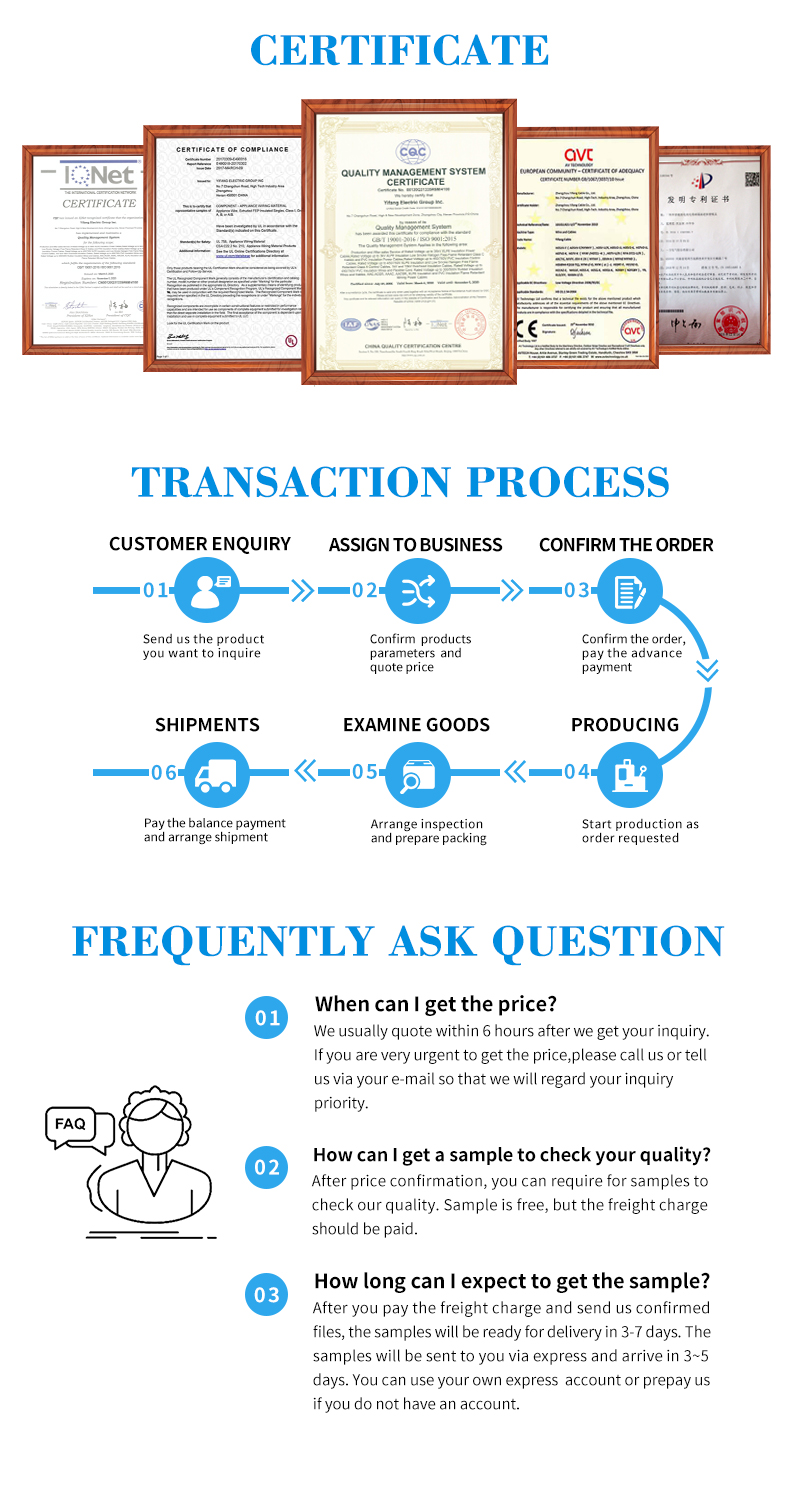

AAAC Conductor consists of aluminum alloy wires. AAAC conductors involved in this standard belongs to ASTER family.

Features

1.Good corrosion resistance

AAAC has good corrosion resistance because it consists only of aluminum alloy wires.It has better corrosion resistance than ACSR.

2.Better strength to weight ratio

Compared with ACSR,AAAC can get better strength to weight ratio and provide improved electrical properties.

Application

This conductor is mainly used for overhead power transmission. AAAC can be used in Medium and High transmission lines of various voltage levels.Now it has been widely used in power lines across large rivers, heavy ice areas and other special geographical features.

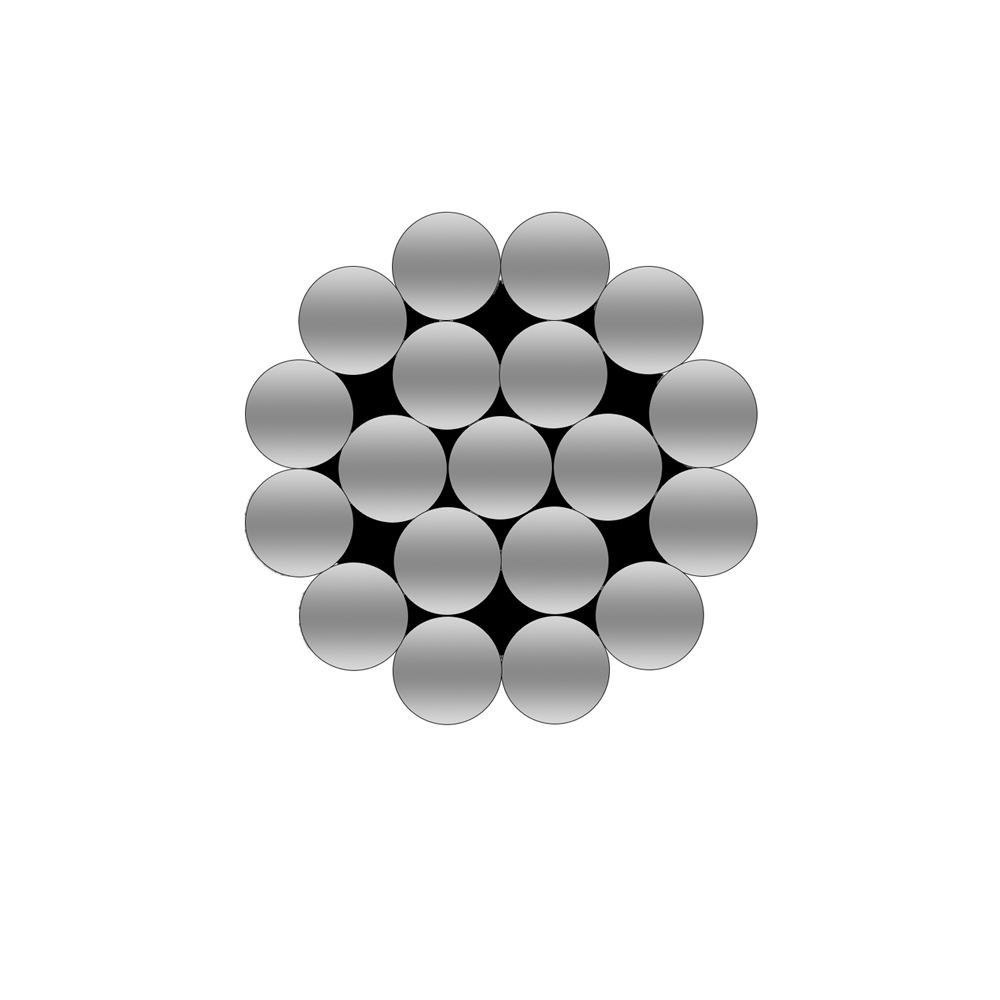

Construction

Aluminum alloy wires, concentrically stranded.

Performance

| Code Word | Calculated sectional area mm2 | Stranding No./mm | Overall diameter mm | Weight kg/km | Breaking Load kg | Max.DC Resistance at 20℃ohm/km |

| ASTER 22 | 21.99 | 7/2.0 | 6 | 60.2 | 710 | 1.5 |

| ASTER 34.4 | 34.36 | 7/2.5 | 7.5 | 94 | 1105 | 0.958 |

| ASTER 54.6 | 54.55 | 7/3.15 | 9.45 | 149 | 1155 | 0.603 |

| ASTER 75.5 | 75.54 | 19/2.25 | 11.25 | 208 | 2430 | 0.438 |

| ASTER 117 | 116.98 | 19/2.8 | 14 | 322 | 3765 | 0.283 |

| ASTER 148 | 148.01 | 19/3.15 | 15.75 | 407 | 4765 | 0.224 |

| ASTER 181.6 | 181.62 | 37/2.5 | 17.5 | 500 | 5845 | 0.183 |

| ASTER 228 | 227.83 | 37/2.8 | 19.6 | 627 | 7340 | 0.146 |

| ASTER 288 | 288.34 | 37/3.15 | 22.05 | 794 | 9280 | 0.115 |

| ASTER 366 | 366.22 | 37/3.55 | 24.85 | 1009 | 11785 | 0.0905 |

| ASTER 570 | 570.22 | 61/3.45 | 31.05 | 1574 | 18360 | 0.0583 |

| ASTER 851 | 850.66 | 91/3.45 | 37.95 | 2354 | 27390 | 0.0391 |

| ASTER 1144 | 1143.51 | 91/4.0 | 44 | 3164 | 36260 | 0.0292 |

| ASTER 1600 | 1595.93 | 127/4.0 | 52 | 4425 | 50640 | 0.0206 |