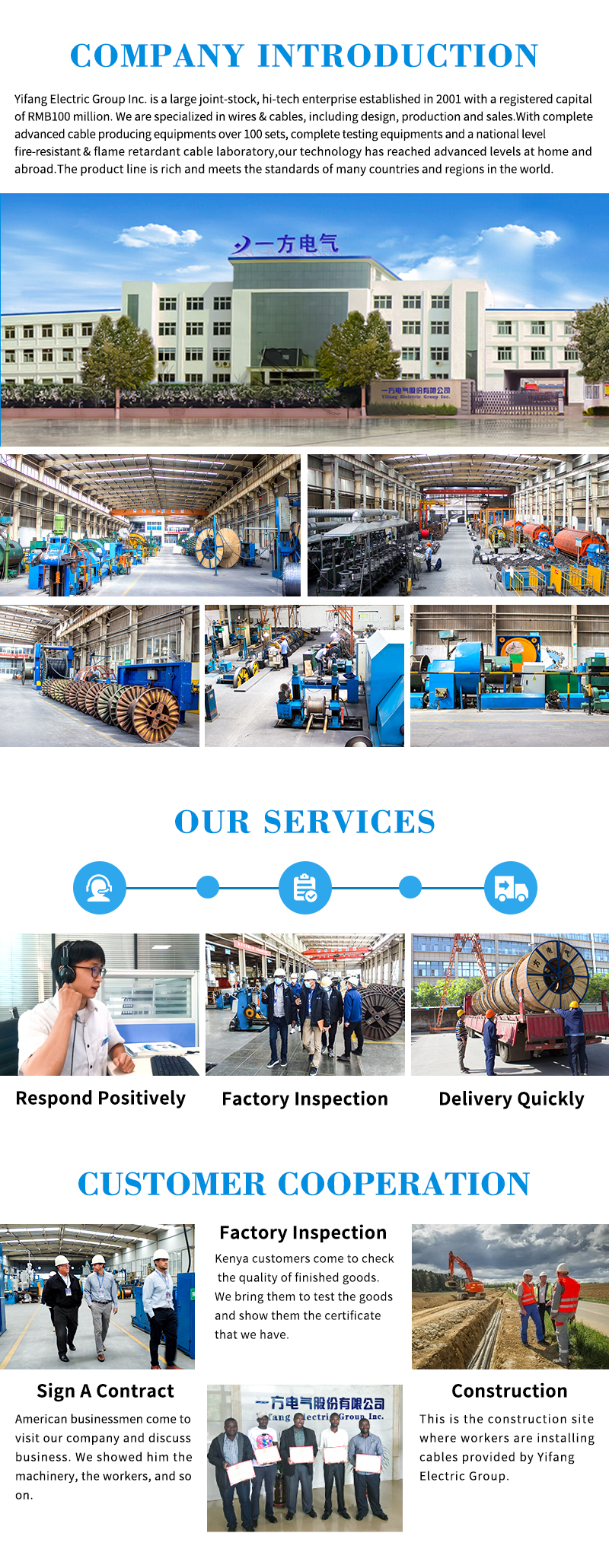

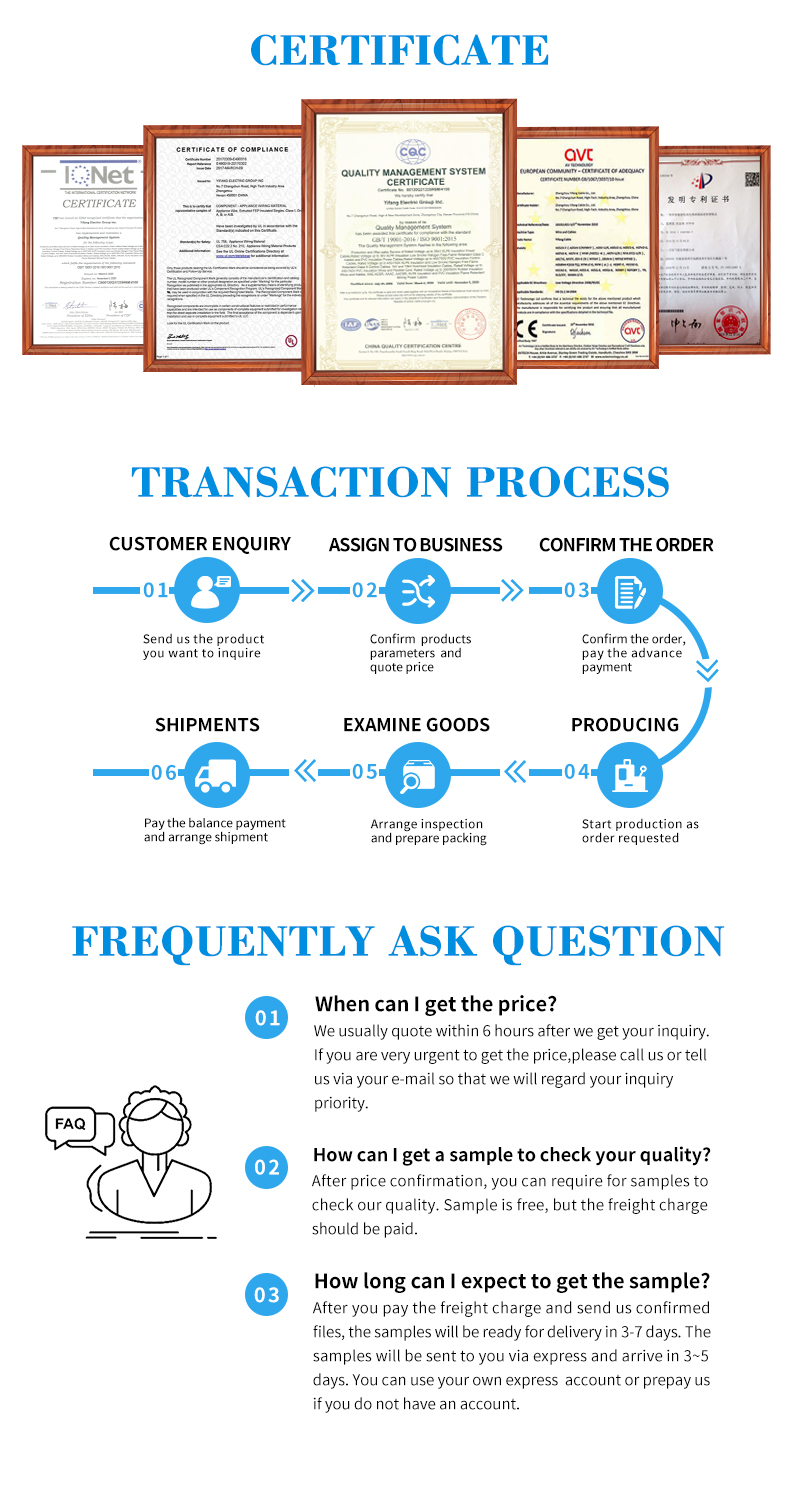

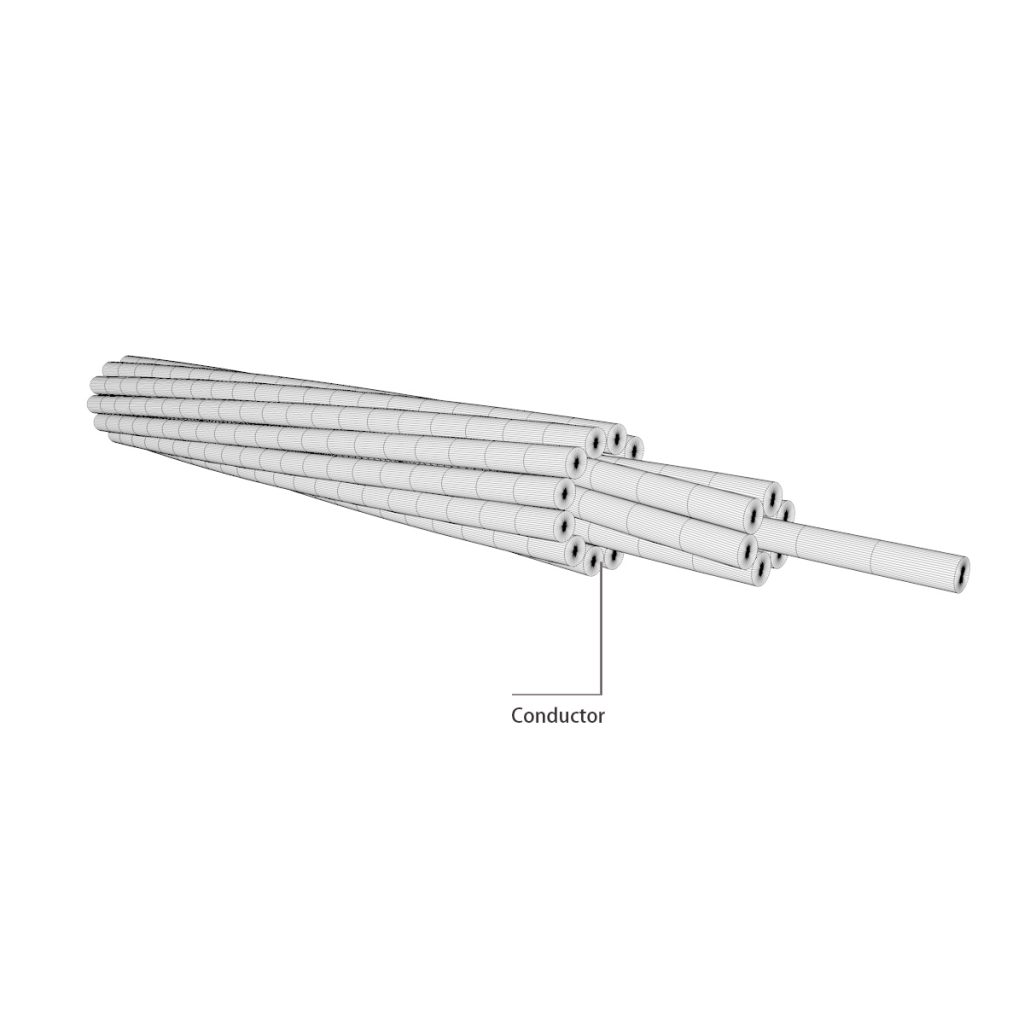

Bare copper, solid or concentrically stranded. There are three varieties of copper: hard, moderately hard, and soft.

Also,we produce the this conductor according to standards BS7884, ASTM B8, NF C34-110, IEC 61089, DIN 48201-1 and so on.

Features

- Uniform and firm hot-dip zinc coating.

- Bright and clean surface.

- Excellent corrosion resistance.

Application

For overhead transmission and distribution applications, solid stranded bare copper. For uninsulated connections, jumpers, and grounding in electrical construction, the more elastic stranded conductors are appropriate.

Construction

Bare copper, solid or stranded. Available in tempers hard, medium-hard, or soft. In the hard and medium hard states, the multi-strand conductors are stranded concentrically, while in the soft tensioned state, combined single-strand stranding is used.

Performance

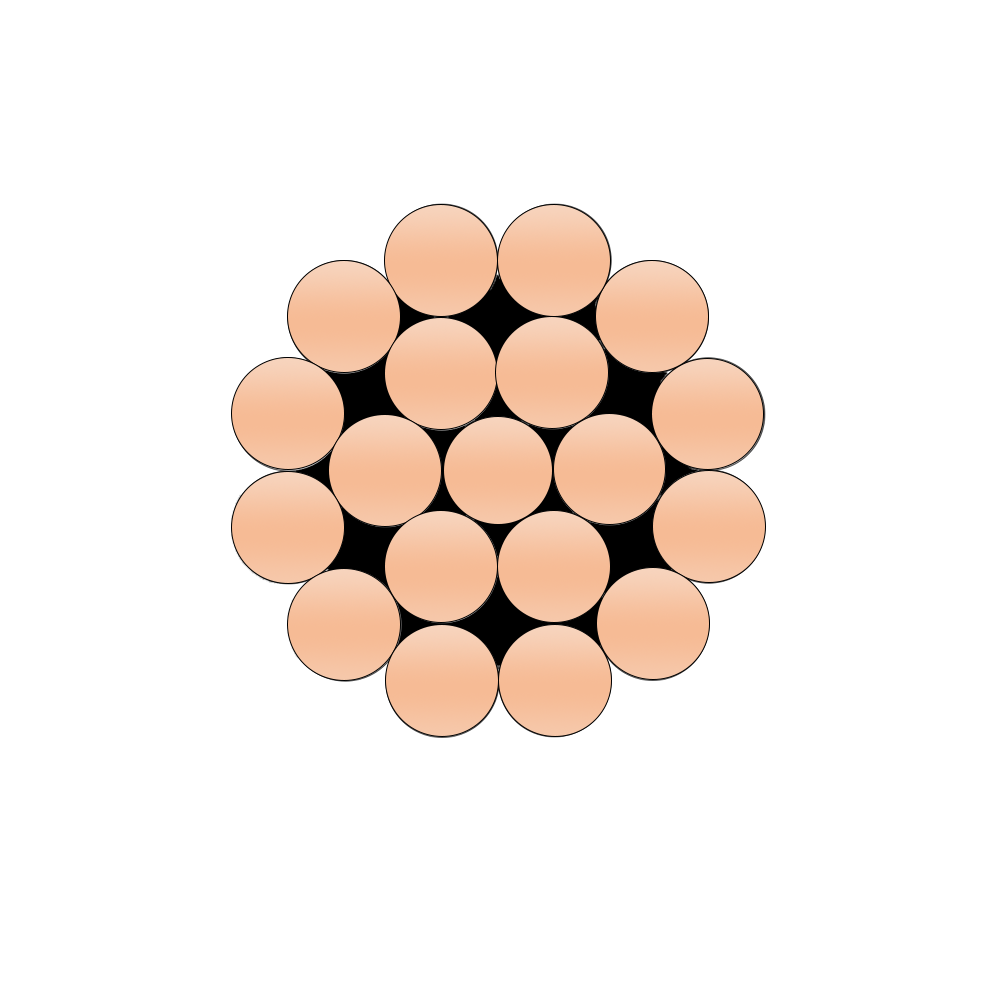

Diameters, Areas, and Mass of Concentric-Lay-Stranded Copper Conductors

| Size of Conductor | Size of Conductor | Nominal Conductor Diameter, inA Concentric Strand | Nominal Conductor Diameler, inA Concentric Strand | Nominal Conductor Diameler, inA Concentric Strand | Nominal Conductor Diameler, inA Concentric Strand | Nominal Conductor Diameler, inA Concentric Strand | Mass | Mass | dc Resistance at 20°C | dc Resistance at 20°C | |

| cmil or AWG numbers | mm2 | Class A A | Class A | Class B | Reverse Concentric Compreseed Class B Diameter in | Unilay Compressed Diameter in | Area in2 | lbs/1000 ft | kg/km | Ω /1000 ft | Ω /km |

| *5 000 000 cmil | 2530 | - | 2.580 | 2 581 | - | - | 3.927 | 15 890 | 23 649 | 0.00218 | 0.00715 |

| 4 500 000 cmil | 2280 | - | 2.448 | 2.448 | - | - | 3.534 | 14 300 | 21 283 | 0.00242 | 0.00794 |

| 4 000 000 cmil | 2030 | - | 2.307 | 2 309 | - | - | 3.142 | 12 590 | 18 738 | 0.00270 | 0.00888 |

| 3 500 000 cmil | 1770 | - | 2.158 | 2159 | - | - | 2.749 | 11 020 | 16 401 | 0.00308 | 0.0101 |

| *3 000 000 cmil | 1520 | - | 1.998 | 1.998 | - | - | 2.356 | 9353 | 13 920 | 0.00356 | 0.0117 |

| *2 500 000 cmil | 1270 | - | 1.823 | 1. .824 | - | - | 1.963 | 7 794 | 11 600 | 0.00427 | 0.0140 |

| *2 000 000 cmil | 1010 | - | 1.630 | 1. .632 | 1.583 | 1.533 | 1.571 | 6175 | 9 190 | 0.00529 | 0.0174 |

| 1 900 000 cmil | 963 | - | 1. 590 | 1. .590 | 1.542 | 1.494 | 1.492 | 5 866 | 8 730 | 0.00557 | 0.0183 |

| 1 800 000 omil | 912 | - | 1. 547 | 1. .548 | 1.502 | 1.454 | 1.414 | 5558 | 8 272 | 0.00588 | 0.0193 |

| *1 750 000 cmil | 887 | - | 1.526 | 1.526 | 1 .480 | 1.434 | 1.374 | 5 403 | 8 041 | 0.00604 | 0.0198 |

| 1 700 000 cmil | 861 | - | 1.504 | 1. 504 | 1.459 | 1.413 | 1.335 | 5249 | 7812 | 0.00622 | 0.0204 |

| 1 600 000 cmil | 801 | - | 1.459 | 1.459 | 1.415 | 1.371 | 1.257 | 4 940 | 7352 | 0.00661 | 0.0217 |

| *1 500 000 cmil | 760 | - | 1.411 | 1.412 | 1.370 | 1.327 | 1.178 | 4 631 | 6 892 | 0.00705 | 0.0231 |

| 1 400 000 cmilt | 709 | - | 1. 364 | 1. .364 | 1.323 | 1.282 | 1.100 | 4 323 | 6 435 | 0.00756 | 0.0248 |

| 1 300 000 cmil | 659 | - | 1.314 | 1.315 | 1.275 | 1.236 | 1.021 | 4 014 | 5974 | 0.00814 | 0.0267 |

| *1 250 000 cmil | 633 | - | 1.288 | 1. .289 | 1.250 | 1.212 | 0.9817 | 3859 | 5 743 | 0.00846 | 0.0278 |

| 1 200 000 cmil | 608 | - | 1.263 | 1.263 | 1.225 | 1.187 | 0.9425 | 3 705 | 5514 | 0.00882 | 0.0289 |

| 1 100 000 cmil | 557 | - | 1. 209 | 1. 209 | 1.173 | 1.137 | 0.8639 | 3396 | 5 054 | 0.00962 | 0.0316 |

| *1 000 000 cmil | 507 | 1.151 | 1.152 | 1.152 | 1.117 | 1.084 | 0.7854 | 3088 | 4 596 | 0.0106 | 0.0348 |

| 900 000 cmil | 456 | 1.092 | 1.094 | 1.094 | 1.060 | 1.028 | 0.7069 | 2779 | 4 136 | 0.0118 | 0.0387 |

| *800 000 cmil | 405 | 1.029 | 1.031 | 1.031 | 1.000 | 0.969 | 0.6283 | 2470 | 3676 | 0.0132 | 0.0433 |

| *750 000 cmil | 380 | 0.997 | 0.998 | 0.998 | 0.968 | 0.939 | 0.5800 | 2316 | 3447 | 0.0141 | 0.0462 |

| *700 000 cmil | 355 | 0.963 | 0.964 | 0.964 | 0.935 | 0.907 | 0.5498 | 2161 | 3216 | 0.0151 | 0.0495 |

| 650 000 cmil | 329 | 0.928 | 0.929 | 0.929 | 0.901 | 0.874 | 0.5106 | 2007 | 2 987 | 0.0163 | 0.0535 |

| *600 000 cmil | 304 | 0.891 | 0.891 | 0.893 | 0.866 | 0.840 | 0.4712 | 1 853 | 2 758 | 0.0176 | 0.0578 |

| 550 000 cmil | 279 | 0.853 | 0.853 | 0.855 | 0.829 | 0.804 | 0.4320 | 1 698 | 2527 | 0.0192 | 0.0630 |

| *500 000 cmil | 253 | 0.811 | 0.813 | 0.813 | 0.789 | 0.766 | 0.3927 | 1 544 | 2298 | 0.0212 | 0.0695 |

| 450 000 cmil | 228 | 0.770 | 0.772 | 0.772 | 0.749 | 0.727 | 0 3534 | 1 389 | 2 067 | 0.0235 | 0.0771 |

| *400 000 cmil | 203 | 0.726 | 0.726 | 0.728 | 0.706 | 0.685 | 0.3142 | 1 235 | 1 838 | 0.0264 | 0.0866 |

| *350 000 cmil | 177 | 0.710 | 0.679 | 0.681 | 0.661 | 0.641 | 0.2749 | 1 081 | 1 609 | 0.0302 | 0.0991 |

| *300 000 cmil | 152 | 0.657 | 0.629 | 0.630 | 0.611 | 0.594 | 0.2356 | 926.3 | 1 378.6 | 0.0353 | 0.116 |

| *250 000 amil | 127 | 0.600 | 0.574 | 0.575 | 0.558 | 0.542 | 0.1963 | 771.9 | 1148.8 | 0.0423 | 0.139 |

| * No.0000 | 107 | 0.522 | 0 522 | 0.528 | 0.512 | 0.498 | 0.1662 | 653.1 | 972.0 | 0.0500 | 0.164 |

| " No.000 | 85.0 | 0.464 | 0.464 | 0.470 | 0.456 | 0.443 | 0.1318 | 518.1 | 771.1 | 0.0630 | 0.207 |

| * No. 00 | 67.4 | 0.414 | 0.414 | 0.419 | 0.405 | 0.395 | 0.1045 | 410.9 | 611.5 | 0.0795 | 0.261 |

| *No.0 | 53.5 | 0.368 | 0.368 | 0.373 | 0.362 | 0.352 | 0.08289 | 325.8 | 484.9 | 0.100 | 0.328 |

| * No, 1,3 wire | 42.4 | 0.360 | - | - | - | - | 0.06573 | 255.9 | 380.9 | 0.126 | 0.413 |

| * No. 1 | 42.4 | - | 0.328 | 0.332 | 0.322 | 0.313 | 0.06573 | 258.4 | 384.6 | 0.126 | 0.413 |

| *No.2,3wire | 33.6 | 0.320 | - | - | - | - | 0.05213 | 202.9 | 301.9 | 0.159 | 0.522 |

| *No.2 | 33.6 | - | 0.292 | 0.292 | 0.283 | - | 0.05213 | 204.9 | 304.9 | 0.159 | 0.522 |

| *No.3.3wire | 26.7 | 0.285 | - | - | - | - | 0.04134 | 160.9 | 239.5 | 0.201 | 0.659 |

| "No.3 | 26.7 | 0.260 | 0.260 | 0.252 | - | 0.04134 | 162.5 | 241.9 | 0.201 | 0.659 | |

| *No. 4, 3 wire | 21.2 | 0.254 | - | - | - | - | 0.03278 | 127.6 | 189.9 | 0.253 | 0.830 |

| "No.4 | 21.2 | - | 0232 | 0.232 | 0.225 | - | 0.03278 | 128.9 | 191.8 | 0.253 | 0.830 |

| * No.5 | 16.8 | - | - | 0.206 | 0.200 | - | 0.02600 | 102.2 | 152.1 | 0.319 | 1.05 |

| *No. 6 | 13.3 | - | - | 0.184 | 0.178 | - | 0.02062 | 81.05 | 120.63 | 0.403 | 1.32 |

| * No.7 | 10.6 | - | - | 0.164 | 0.159 | - | 0.01635 | 64.28 | 95.67 | 0.509 | 1.67 |

| * No.8 | 8.37 | - | - | 0.146 | 0.142 | - | 0.01297 | 50.97 | 75.86 | 0.640 | 2.10 |

| * No.9 | 6.63 | - | - | 0.130 | 0.126 | - | 0.01028 | 40.42 | 60.16 | 0.809 | 2.65 |

| * No. 10 | 5.26 | - | - | 0.116 | 0.113 | - | 0.008155 | 32.06 | 47.72 | 1.02 | 3.35 |

| * No. 12 | 3.31 | - | - | 0.0915 | 0.089 | - | 0.005129 | 20.16 | 30.00 | 1.63 | 5.35 |

| * No.14 | 2.08 | - | - | 0.0726 | 0.071 | - | 0.003225 | 12.68 | 18.87 | 2.58 | 8.46 |

| * No. 16 | 0.823 | - | - | 0.0576 | - | - | 0.002028 | 7.974 | 11.868 | 4.1 | 13.45 |

| *No.18 | 0.519 | - | - | 0.0456 | - | - | 0.001276 | 5.015 | 7.484 | 6.54 | 21.46 |

| * No.20 | 0.519 | - | - | 0.0363 | - | - | 0.0008023 | 3.154 | 4.694 | 10.3 | 33.8 |

| * No.22 | 0.324 | - | - | 0.0288 | - | - | 0.0005067 | 1.992 | 2.965 | 16.4 | 53.8 |

| * No.24 | 0.205 | - | - | 0.0228 | - | - | 0.0003176 | 1.249 | 1.859 | 26.1 | 85.6 |

1.To calculate the nominal diameters of Class C or Class D conductors or of any concentric-lay-stranded conductors made from round wires of uniform diameters, multiply the diamter of an individual wire (as given in Table 1) by that one of the following facors which applies:

2.Resistances (dc) apply to Class B. C. and D stranding. For other classes of stranding.refer to Test Method B193. Reistance (dc) based on annealed copper .

3.For conductors manfactured for subsequent coverning or insulating .