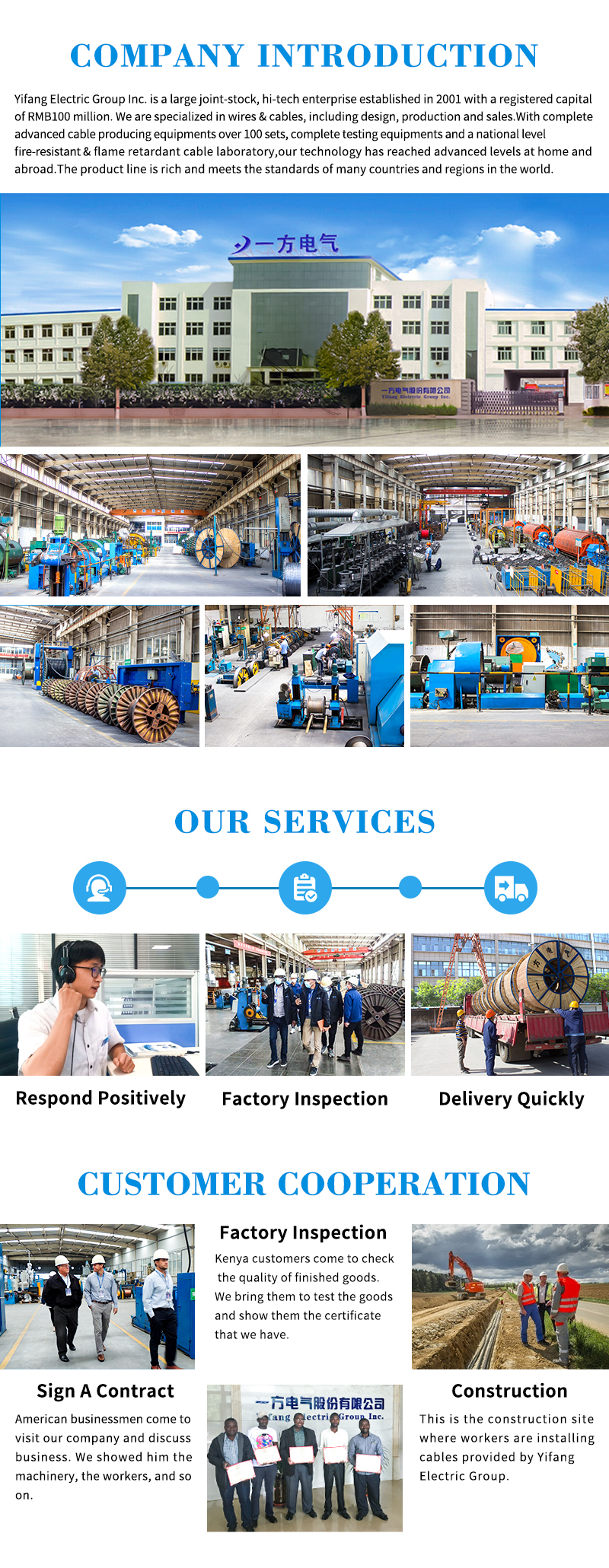

Galvanized steel strands can be used for a variety of purposes such as power strands for insulating overhead strands, tie-down or support wires.

Steel wires for strands meet the requirements of DIN 48201-3.

Features

Galvanized steel wire is perfect for mass-produced corrosion-resistant wire products due to its low cost and ease of production.

To increase its corrosion resistance, galvanized steel wire strand is exposed to a galvanizing procedure.

Good reliability and high strength.

Application

Galvanized steel strands are used as power strands for insulated overhead strands, tie-down cables or support cables, etc.

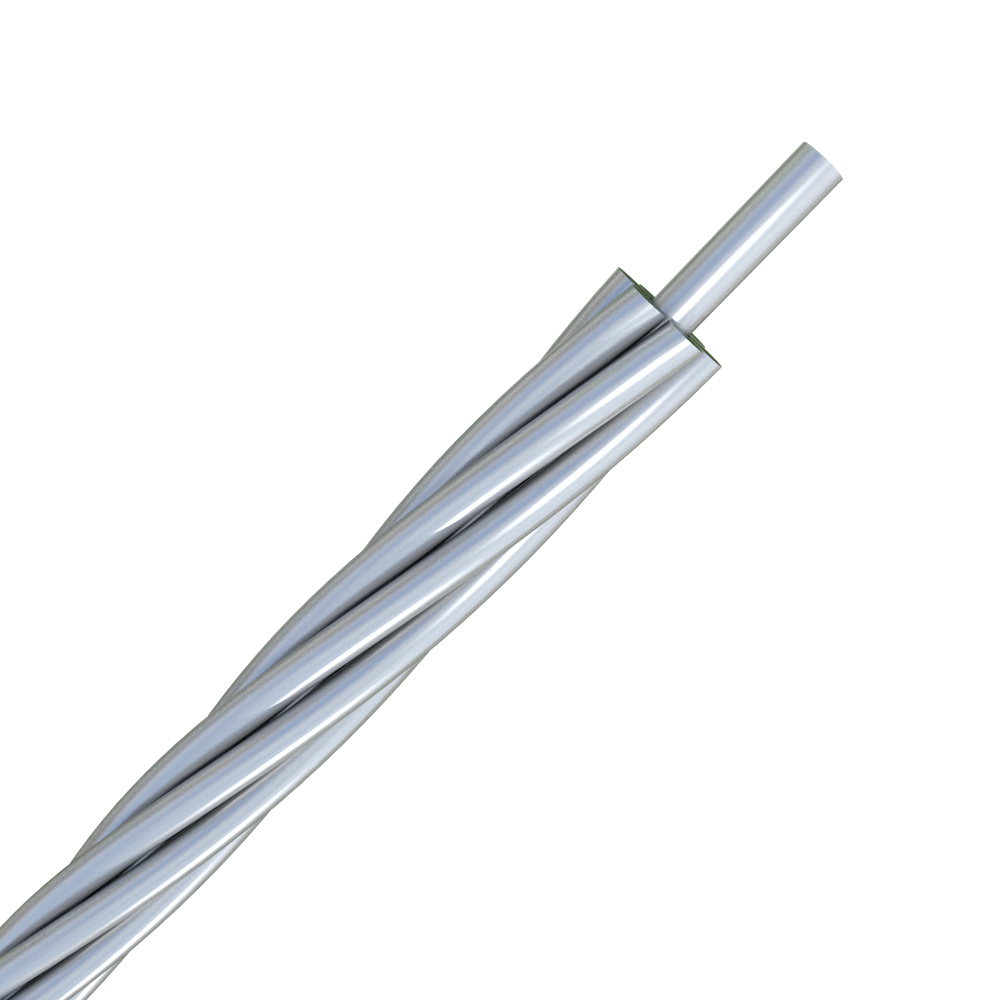

Construction

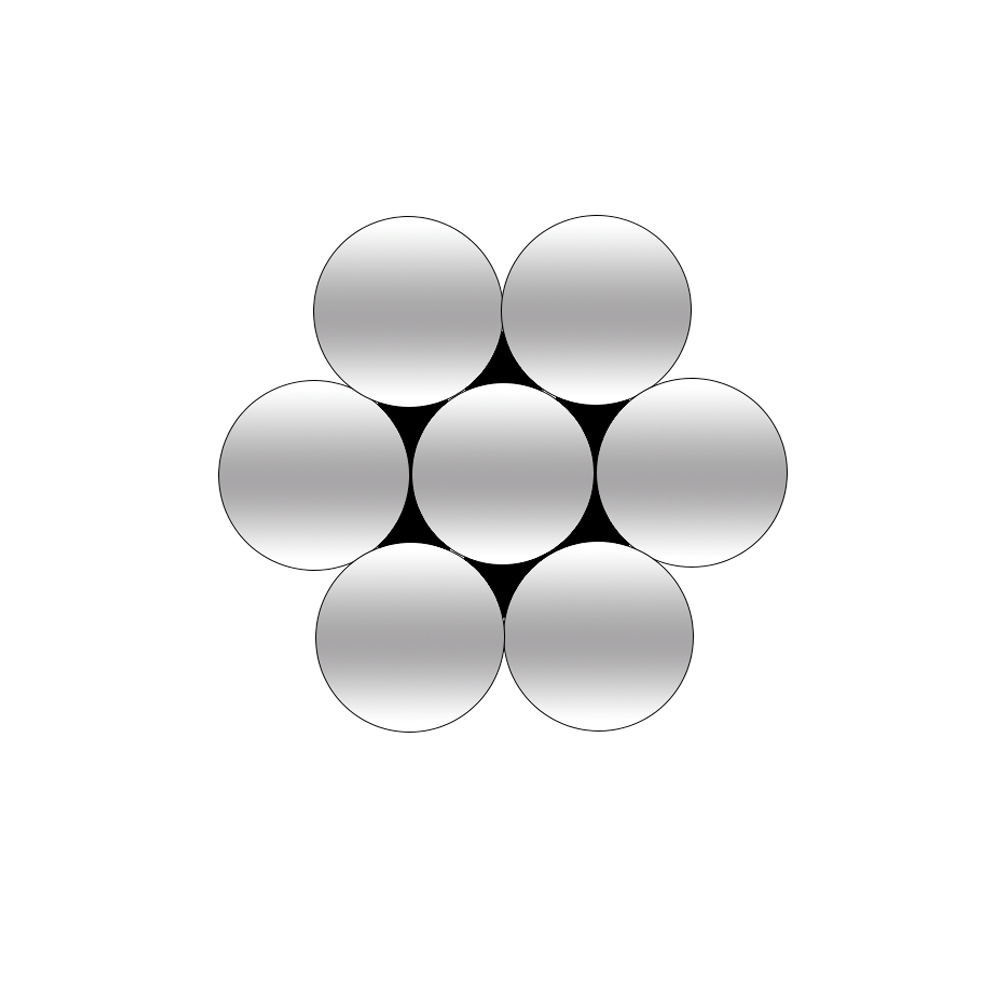

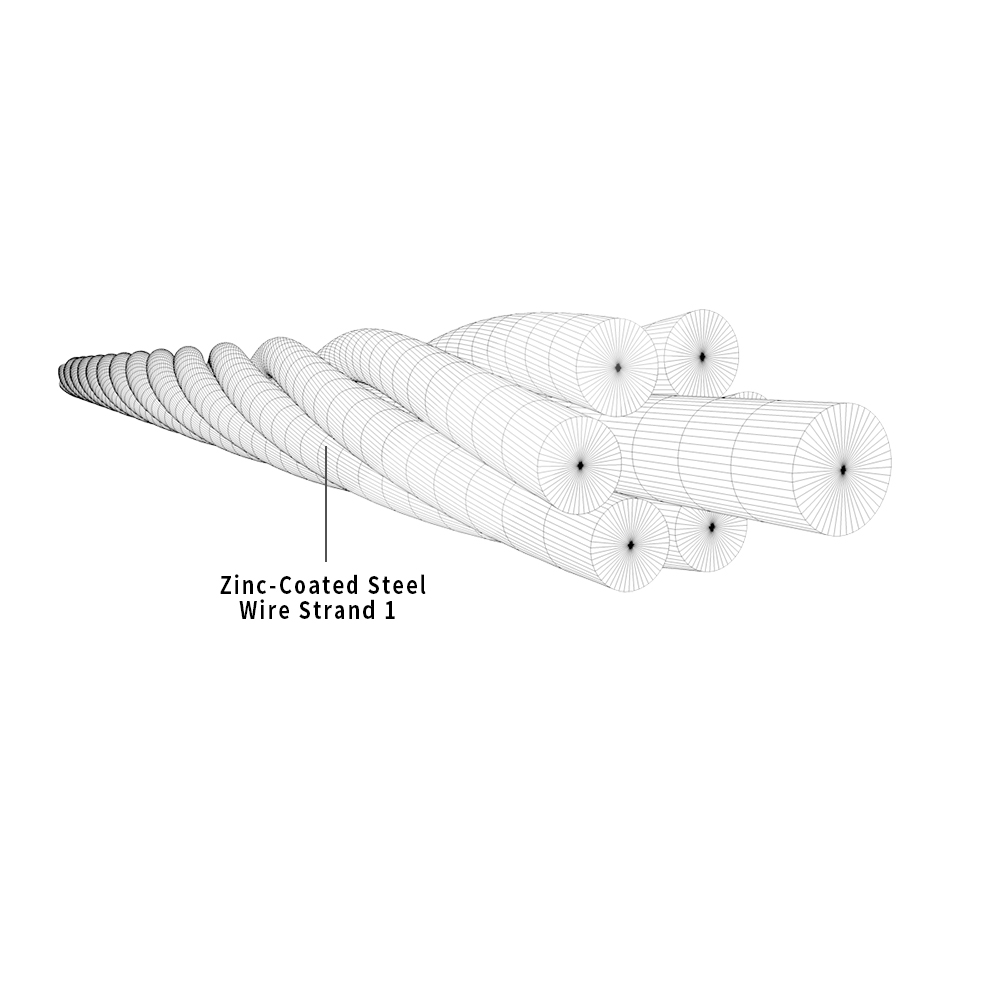

Concentrically stranded galvanized steel wire strand.

The outer layer of all strands is right-handed. The pitch diameter ratio of the outer layer of the stranded wire is 10 to 14 times.

There are 1×7 and 1×19 twisted wire structures.

Performance

| Nominal section mm² | Nominal cross-section mm² | Wire Number | Wire Diameter mm | Rope Diameter mm | Weight kg /km | Calculated breaking strength St I | Calculated breaking strength St II | Calculated breaking strength St III | Calculated breaking strength St IV |

| 25 | 24.25 | 7 | 2.10 | 6.3 | 192 | 8.98 | 15.9 | 30.18 | 36.17 |

| 35 | 34.36 | 7 | 2.50 | 7.5 | 272 | 12.73 | 22.52 | 42.76 | 51.25 |

| 50 | 49.48 | 7 | 3.00 | 9.0 | 391 | 18.33 | 32.43 | 61.58 | 73.8 |

| 48.35 | 19 | 1.80 | 9.0 | 384 | 17.91 | 31.69 | 61.07 | 72.11 | |

| 70 | 65.81 | 19 | 2.10 | 10.5 | 522 | 24.38 | 43.14 | 81.9 | 98.16 |

| 95 | 93.27 | 19 | 2.50 | 12.5 | 741 | 34.56 | 61.14 | 116.07 | 139.11 |

| 120 | 116.99 | 19 | 2.80 | 14.0 | 929 | 43.34 | 76.69 | 145.59 | 174.49 |