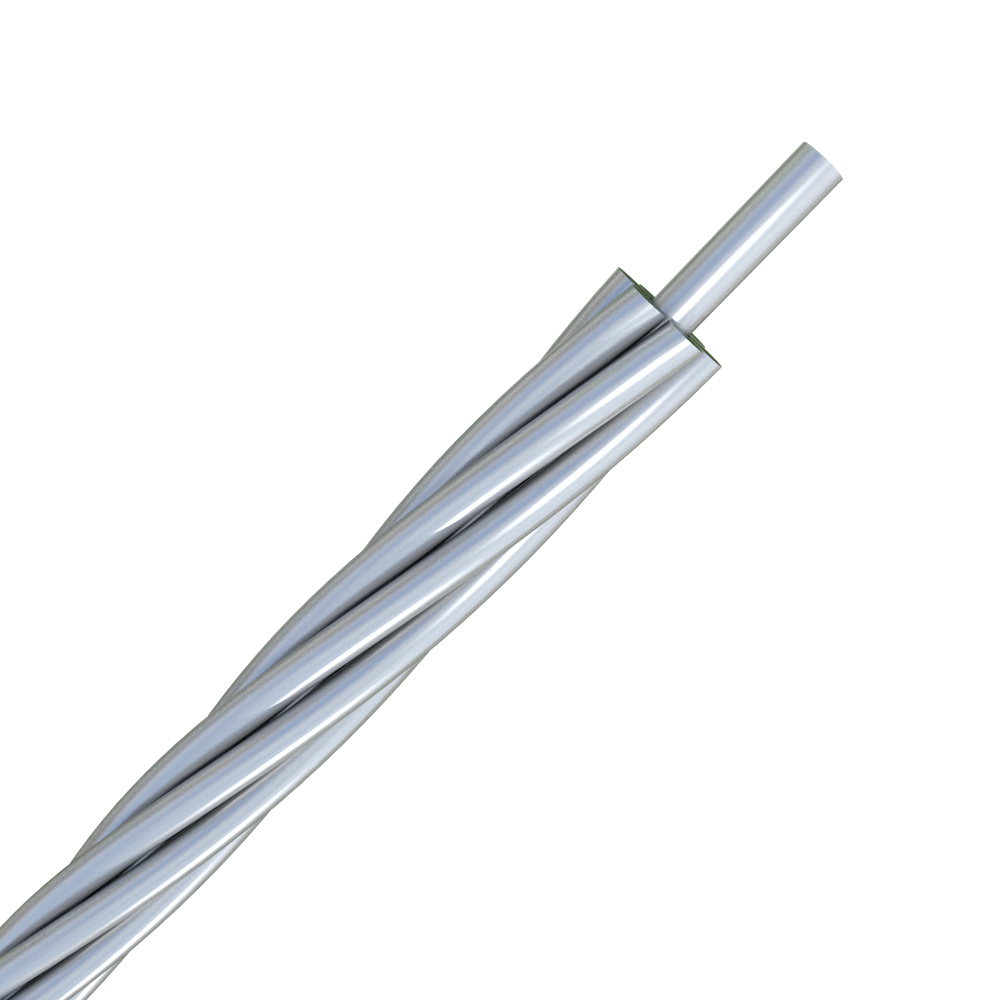

Galvanized steel strands are used to bear tension and are used in power and light industries. Strand strength grades are Grades 11 O, 160, 180, and 220 (800, 11 00, 1300, and 1500). Class A hot-dip and Class A, B, or C electro-galvanized zinc coatings are available for all grades.

Features

Galvanized steel wire is perfect for mass-produced corrosion-resistant wire products because of its low cost and ease of production.

To increase its corrosion resistance, galvanized steel wire strand is exposed to a galvanizing procedure.

Strong and highly reliable.

Application

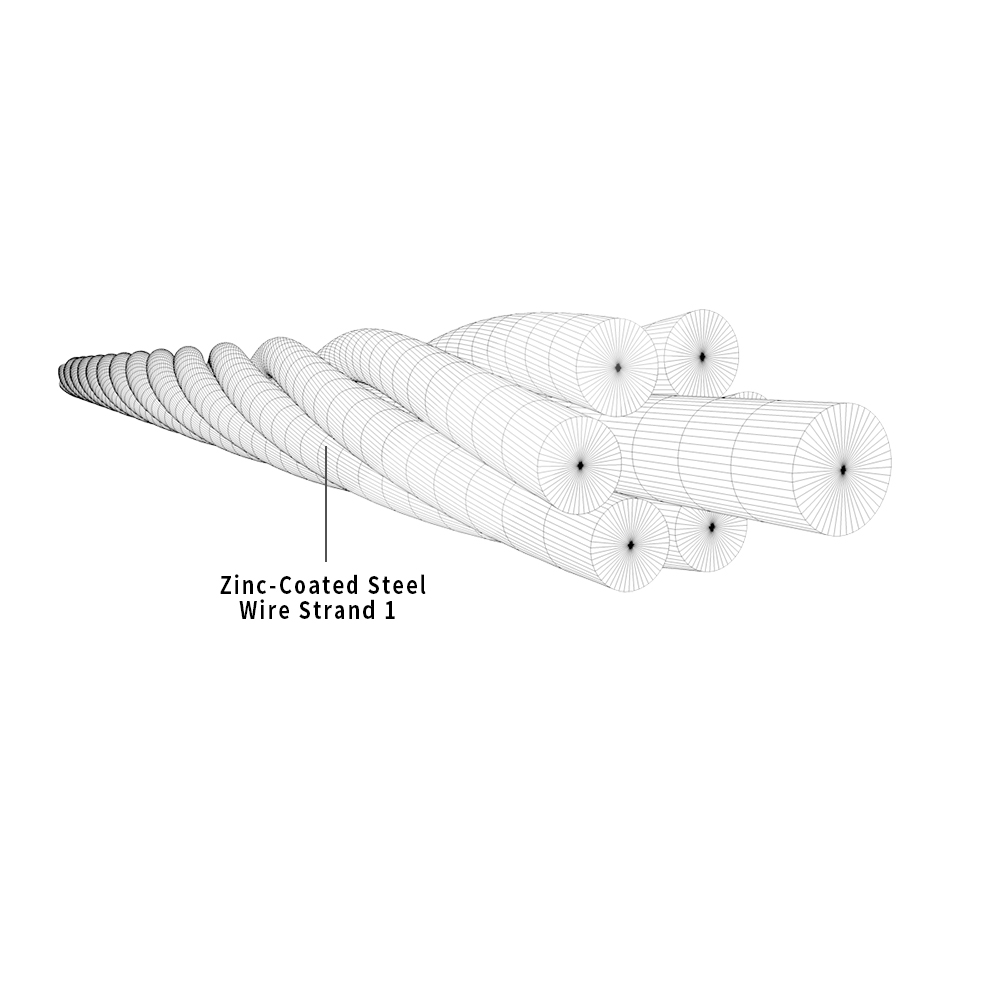

This standard specifies zinc-coated steel wire strand that can be used for guys, suspension wires, span wires, and overhead ground wires.

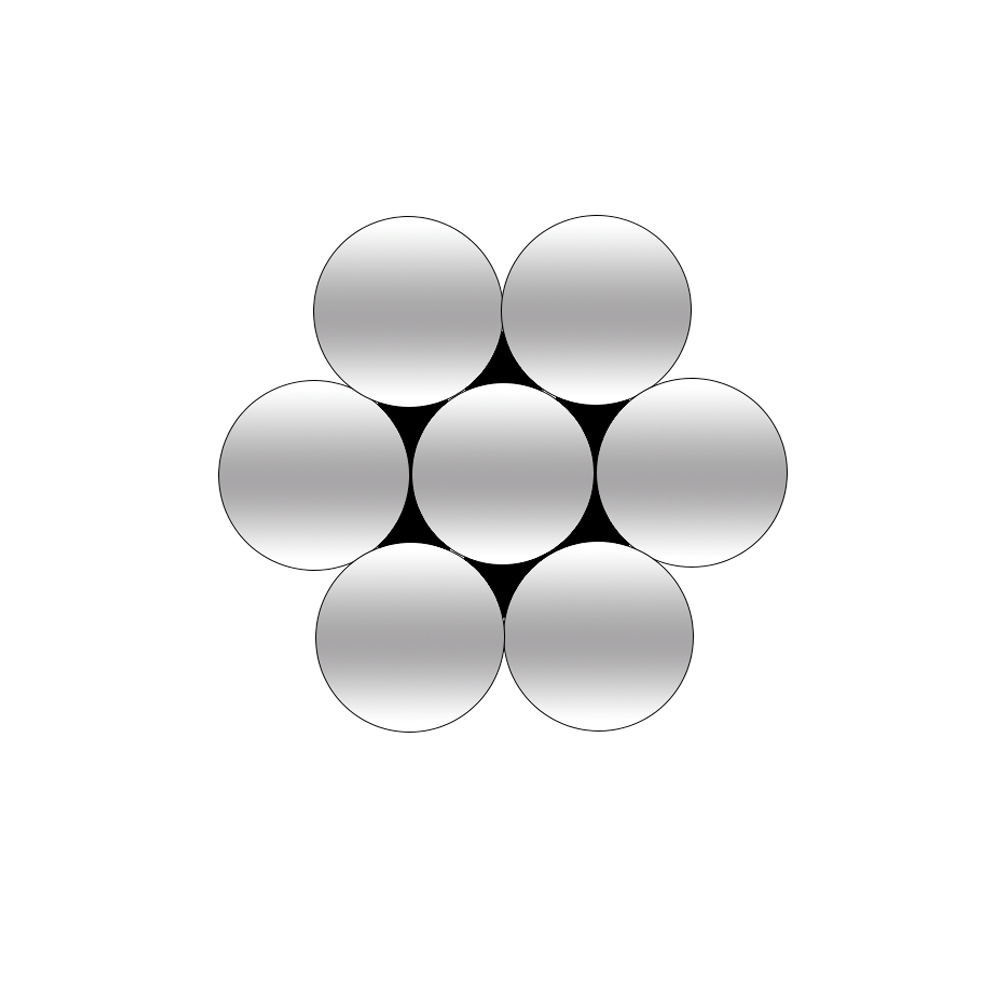

Construction

Concentrically stranded galvanized steel wire strand.

The outer layer of all strands is left-handed. The upper limit of the stranded wire pitch diameter ratio is not more than 16 times.

Construction features include strands containing 7, 19, or more than 19 wires.

Performance

| Designated strand size,mm | Nominal strand diamerter,mm | Nominal wire diamerter,mm | Nominal metallic cross-sectional area of the strand,mm2 | Number of wires | Minimum breaking load ,kn Grade 800 | Minimum breaking load ,kn Grade 1000 | Minimum breaking load ,kn Grade 1300 | Minimum breaking load ,kn Grade 1500 | Approximate mass, kg/1000m |

| 5 | 5.1 | 1.7 | 15.9 | 7 | 12.0 | 16.5 | 19.5 | 22.5 | 130 |

| 6 | 6.3 | 2.1 | 24.2 | 7 | 18.0 | 25.0 | 30.0 | 34.5 | 190 |

| 7 | 7.2 | 2.4 | 31.7 | 7 | 24.0 | 33.0 | 39.0 | 45.0 | 250 |

| 8 | 8.4 | 2.8 | 43.1 | 7 | 33.0 | 45.0 | 53.0 | 61.5 | 340 |

| 9 | 9.0 | 3.0 | 49.5 | 7 | 37.5 | 52.0 | 61.0 | 70.5 | 390 |

| 10 | 10.8 | 3.6 | 71.3 | 7 | 54.0 | 74.5 | 88.0 | 101.5 | 560 |

| 12 | 12.6 | 4.2 | 97.0 | 7 | 74.0 | 101.0 | 120.0 | 138.0 | 760 |

| 14 | 14.4 | 2.8/3.2 | 118.9 | 19 | 85.5 | 118.0 | 139.0 | 160.5 | 930 |

| 16 | 16.2 | 3.2/3.4 | 153.8 | 19 | 110.0 | 152.0 | 180.0 | 207.5 | 1210 |

| 18 | 18.2 | 3.6/3.8 | 194.6 | 19 | 140.0 | 192.5 | 227.5 | 263.0 | 1530 |

| 20 | 20.2 | 4.0/4.2 | 240.0 | 19 | 173.0 | 237.5 | 281.0 | 324.0 | 1890 |

| 22 | 22.2 | 4.4/4.6 | 290.3 | 19 | 209.0 | 287.0 | 339.5 | 392.0 | 2280 |

| 24 | 24.2 | 4.8/5.0 | 345.4 | 19 | 248.5 | 342.0 | 404.0 | 466.0 | 2710 |

| 26 | 26.8 | 5.3/5.6 | 421.7 | 19 | 303.5 | 418.0 | 493.0 | 569.0 | 3310 |

| 28 | 29 | Dependent upon design | 500 | More than 19 wires | — | — | — | 675 | 4030 |

| 32 | 32 | Dependent upon design | 610 | More than 19 wires | — | — | — | 825 | 4920 |

| 36 | 35 | Dependent upon design | 730 | More than 19 wires | — | — | — | 985 | 5900 |

| 40 | 39 | Dependent upon design | 890 | More than 19 wires | — | — | — | 1200 | 7200 |

| 44 | 45 | Dependent upon design | 1200 | More than 19 wires | — | — | — | 1620 | 9730 |

| 48 | 49 | Dependent upon design | 1400 | More than 19 wires | — | — | — | 1890 | 11350 |

| 52 | 52 | Dependent upon design | 1600 | More than 19 wires | — | — | — | 2160 | 12980 |