What is a submarine cable

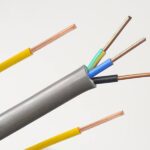

Submarine cables are power cables laid under water in rivers, lakes, and seas, also known as underwater cables. Compared with land cables, there is not much difference in the main insulation. Due to the special construction methods and operating conditions of submarine cables, there are great differences in the structure of armor, metal sheath, and manufacturing length.

Submarine cables are often made into large lengths of the entire cable, and its transportation needs to be coiled. Although short-pitch armor can reduce the coil diameter, short-pitch (8 times the average diameter of the armor) armored submarine cables are easy to knot at the bottom when subjected to high tension during laying, so the general The armor pitch needs to be 12 to 14 times the average diameter of the armor. In order to reduce the coil diameter, some use short-pitch prestressed steel wire or double-layer steel wire armor, and some use armor with the inner and outer layers twisted in opposite directions.

What are the types of submarine cables

- From a structural point of view, it is mainly divided into three-core submarine cables and single-core submarine cables. Most of the medium and low-voltage lines use three-core submarine cables, and most of the high-voltage lines use single-core submarine cables.

- From a functional point of view, half a century ago, the submarine cable only had a simple power transmission function, and now the submarine cable integrates two functions, effectively realizing the transmission of power and signals on the same cable.

- From the perspective of insulation composition, it is divided into oil-filled insulated submarine cables and extruded plastic insulated submarine cables.

- From the perspective of load type, it can be divided into DC submarine cable and AC submarine cable. DC submarine cable is characterized by low loss and easy to realize long-distance power transmission. However, the application experience of DC submarine cable is not rich. The cost is high, and the loss of the AC submarine cable is large, but the operation and maintenance technology is mature, and the supporting construction cost is small.

How to connect submarine cables

- Routing investigation of submarine cables

The cable route investigation before the submarine cable laying includes: clearing the water depth, topography, and shallow strata profile measurement of the offshore routing area; sediment surface sampling, columnar sampling and static penetrating survey; also includes traffic and construction conditions reflecting the status of marine development activities and obstacles. Recently, the use of advanced GPS post-processing positioning and (CPT) static penetrating sounding technology has greatly improved the survey speed and effect. - Laying of submarine cables

The submarine cable laying project is recognized as a complex and difficult large-scale project by countries all over the world. When laying the cable, control the sailing speed of the laying ship and the release speed of the cable to control the angle of the cable entering the water and the laying tension, so as to avoid damage to the cable due to too small bending radius or too large tension. In shallow seas, if the water depth is less than 200 meters, the cables are buried, while in deep seas, they are laid. The cables are released by the cable laying ship, and the underwater monitor and underwater remote control vehicle are used to continuously monitor and adjust, and control the laying ship. The forward speed, direction and speed of laying the cable can avoid uneven places and rocks to avoid damage to the cable. - Burying protection of submarine cables

In the final stage of construction, the main purpose is to deeply bury the submarine cables to reduce the impact of the complex marine environment on the submarine cables and ensure safe operation. In the sandy land and silt area, use high-pressure flushing to create a trench about 2 meters deep, bury the cable in it, and cover it with the sand next to it; in the coral reef and clay area, use a cutting machine to cut a 0.6-1.2-meter trench For deep trenches, bury the cables in the trenches and backfill them naturally to form protection; in hard rock areas, hard objects such as cement cover plates need to be covered on the cables for protection.